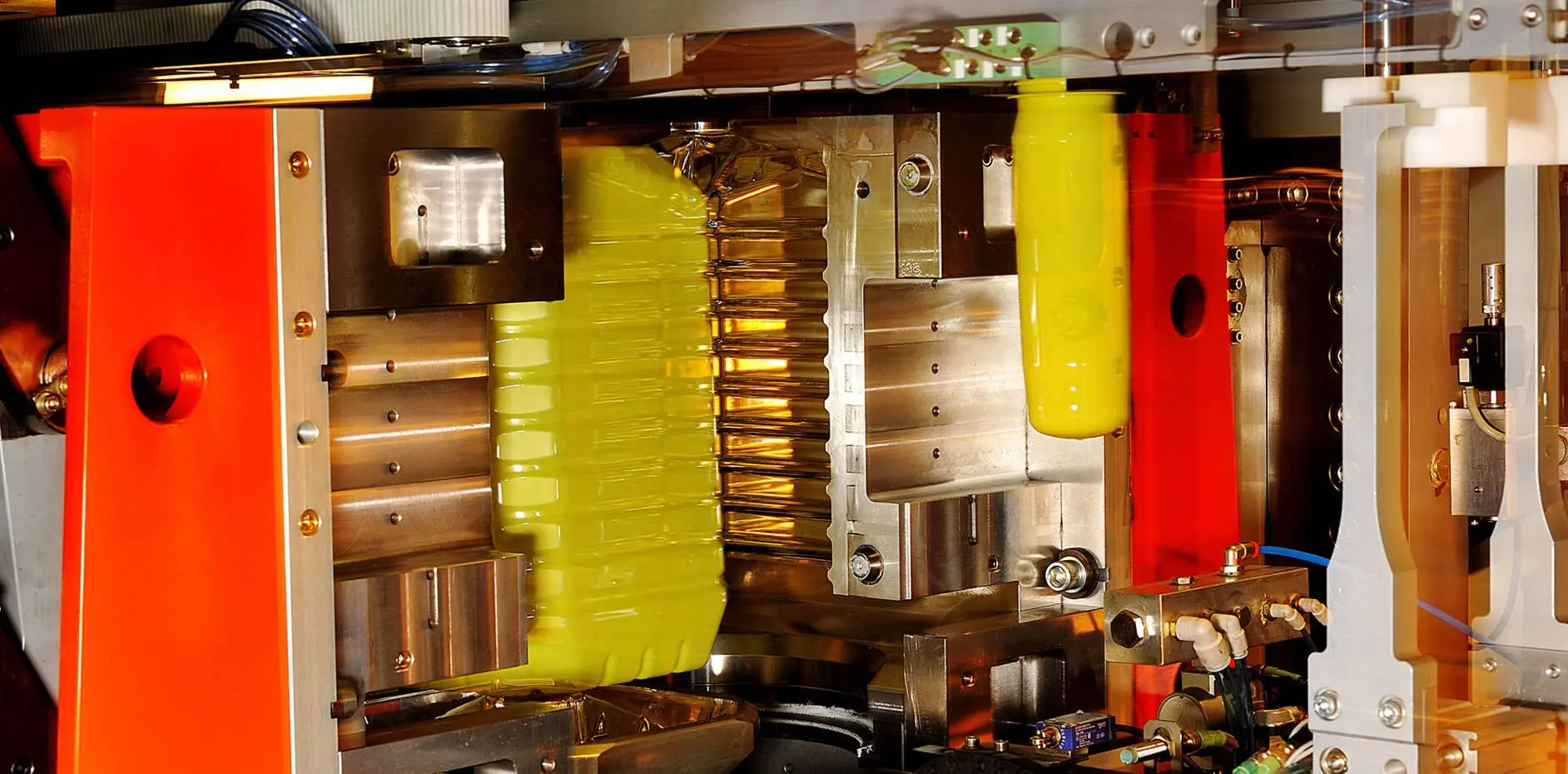

The XTRA range of rotary stretch-blow molding systems is well known for its high output capacity and energy efficiency. That is mainly down to the excellent kinetics of moving components and to the unmatched process angle of 275 degrees. Increasing the process angle provides more time for blowing and in so doing reduces built-in stress in bottles, enabling extremely accurate reproduction of mold surfaces – even the most complex ones.

These and other features make it possible to produce up to 2,800 bottles per hour, per cavity.

Machines are flexible too: they can produce a very wide range of container shapes and sizes, while units designed for hot-fill bottles are just as good at blowing cold-fill types. The time required to switch molds for bottle bodies and necks is very low, so uptime is maximized, and productivity taken to heights that nobody else can match. Flexibility is taken to an even higher level with special versions, such as XTRA PH (Preferential Heating) and XTRA BIG for large size containers.

Contact Us

Contact Us