- Home / XLABL labeller

- SIPA

Roll-fed labeller, designed to apply plastic wrap-around labels with hot-melt glue to cylindrical and shaped PET bottles, full or empty.

It is engineered to perform with unparalleled accuracy, even at varying production speeds. Its flexibility makes it suitable for diverse applications in industries ranging from beverages to personal care, all while ensuring exceptional cost-efficiency and sustainability.

HIGHLIGHTS

/

01

- Flexibility: Highly flexibility in handling a wide range of labels, with varying qualities and thicknesses.

- Performances : Unmatched labelling efficiency, speed and precision, powered by seamless brushless motion technology.

- Cost-effectiveness: Reduced operating costs thanks to efficiency and waste minimization.

- Straight fixed blade :No need of adjustment after quick replacement, excellent cutting quality and extended durability up 200 million cuts.

- Footprint : Compact and ergonomic design with easy operator access, reducing shipment costs and installation time.

- Easy Operation : Ease of use, maintenance and changeover to reduce production downtime.

LABEL REELS MANAGEMENT

/

02

- Dual reel system, controlled by servomotors, for a precise and active unwinding, with web aligner, and mark reading.

- Automatic reel splicing for continuous operation without any machine stop and loose of production.

- Film tensioner and aligner system offering active and electronically controlled tension reduction for a consistently smooth film flow.

TRACTION AND CUTTING ROLLER

/

03

- Patented Cutting System: Highly reliable and long lasting (up to 200 million cuts) with excellent quality and precision.

- Innovative quick-replacement mechanism requires no adjustments, featuring a single screw for the fixed blade.

- Durable blade: Utilizes an extremely resistant sintered hard metal straight fixed blade for extended durability without tooth wear, eliminating label stress.

- Servomotor Control/strong>: Includes a "Pull-Back" function to prevent waste during idle times and a convenient label length self-learning function.

VACUUM TRANSFER DRUM

/

04

- Moves labels from the cutting cylinder to the glue roller and then to the bottle

- Vacuum transfer roller with removable vacuum plate for cleaning, without losing adjustment.

- Optimized vacuum distribution to reduce kw turbine.

- Low weight drum for quick changeover.

- Motion control with brushless servomotor.

GLUE DISTRIBUTION STATION

/

05

- Glue Distribution: Engineered for a precise, consistent and uniform glue application on every label.

- Minimized Consumption: Designed to reduce glue usage and prevent issues like fumes or carbonization.

- Flexible Dosing and Scraping: Adaptable system to meet diverse customer-specific requirements.

- External Insulated Glue Tank: Provides easy access for feeding glue blocks and cleaning without machine downtime.

- Electrically Heated Glue Pipe: Contributes to quicker machine start-up by efficiently heating the glue distributor

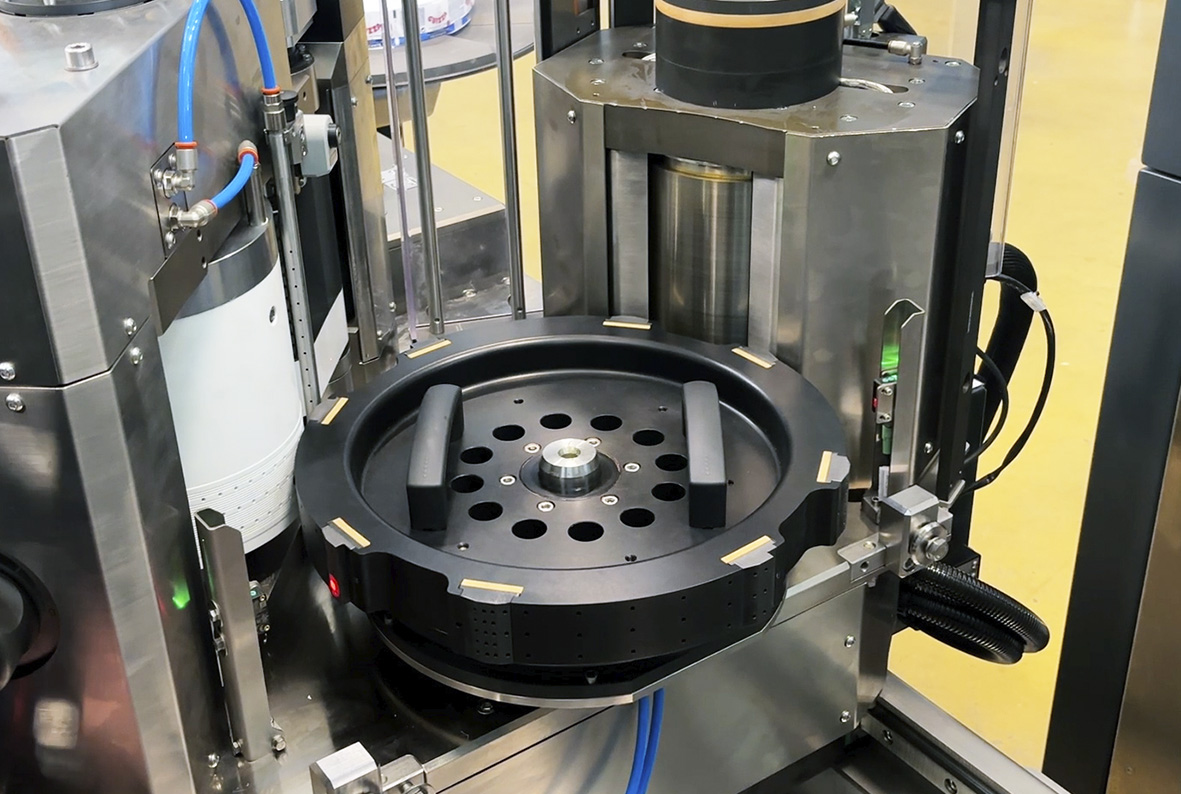

LABELLING CARROUSEL AND BOTTLE HANDLING

/

06

- Brushless motorized carousel: highly precise dynamics

- Self-centring bottle-holding plates equipped with a quick-release system

- Highly precise and flexible cap-pressing heads, also capable of empty bottle pressurization.

- Pneumatic compensation option for a fine adjustment of the top load pressure.

- Automatic adjustment of the head height from HMI.

- Efficient bottle infeed and outfeed with a customized conveyors and handling system.

APPLICATIONS

Extremely complete range allows to handle shrink-packs, cartons, crates, loose container both PET and glass, can and tin containers or jars with metal lids.

-

Discover more/02

- SIPA

Discover the other sections of Secondary Packaging

Explore our comprehensive range of secondary packaging services: from initial design and engineering to prototyping containers that bring your unique packaging vision to life.

Robotic handling systems

06

/

07

/

2025

Robotic handling systems

Learn about our robotic handling systems, offering versatile solutions for complex packaging tasks with high reliability and flexibility.

Depalletisers

06

/

07

/

2025

Depalletisers

Explore our range of depalletisers, engineered to streamline the unloading process with high efficiency and minimal manual input. See the benefits

Palletisers

06

/

07

/

2025

Palletisers

Discover our innovative palletisers, designed to automate the palletizing process with precision and high throughput. Learn how they enhance your production.

News for this products

SIPA Additive: reimagined 3D printing fast prototyping

25

/

02

/

2026

SIPA Additive: reimagined 3D printing fast prototyping

SIPA has officially launched SIPA Additive, a new service designed to provide customers with a fast and cost-effective solution for packaging development. Located at the SIPA HQ Plant, the dedicated...

Intelligence in the mold: SIPA unveils XBRAIN for advanced digital management

While high-performance machinery is the backbone of PET production, the future of manufacturing lies in the data hidden within the mold. SIPA is proud to introduce XBrain, an advanced telemetric and...

Celebrating our sustainability achievements

13

/

01

/

2026

Celebrating our sustainability achievements

Celebrating our sustainability achievements: SIPA earns Gold Medal from Ecovadis With an overall score of 78/100 SIPA has been awarded a Gold medal from EcoVadis Sustainability Rating placing us...

XFORM Progress: From GEN 4 to PRO - setting new standards in high-cavitation PET preform production

12

/

12

/

2025

XFORM Progress: From GEN 4 to PRO - setting new standards in high-cavitation PET preform production

SIPA's XFORM RENEW wins Sustainability Awards 2025 for its efficient PET recycling tech, reducing CO₂ emissions and energy use while lowering costs.

SIPA's XFORM RENEW Wins Top Sustainability Award

13

/

11

/

2025

SIPA's XFORM RENEW Wins Top Sustainability Award

SIPA's XFORM RENEW wins Sustainability Awards 2025 for its efficient PET recycling tech, reducing CO₂ emissions and energy use while lowering costs.

25

/

02

/

2026

SIPA Additive: reimagined 3D printing fast prototyping

SIPA has officially launched SIPA Additive, a new service designed to provide customers with a fast and cost-effective solution for packaging development. Located at the SIPA HQ Plant, the dedicated...

27

/

01

/

2026

Intelligence in the mold: SIPA unveils XBRAIN for advanced digital management

While high-performance machinery is the backbone of PET production, the future of manufacturing lies in the data hidden within the mold. SIPA is proud to introduce XBrain, an advanced telemetric and...

13

/

01

/

2026

Celebrating our sustainability achievements

Celebrating our sustainability achievements: SIPA earns Gold Medal from Ecovadis With an overall score of 78/100 SIPA has been awarded a Gold medal from EcoVadis Sustainability Rating placing us...

12

/

12

/

2025

XFORM Progress: From GEN 4 to PRO - setting new standards in high-cavitation PET preform production

SIPA's XFORM RENEW wins Sustainability Awards 2025 for its efficient PET recycling tech, reducing CO₂ emissions and energy use while lowering costs.

13

/

11

/

2025

SIPA's XFORM RENEW Wins Top Sustainability Award

SIPA's XFORM RENEW wins Sustainability Awards 2025 for its efficient PET recycling tech, reducing CO₂ emissions and energy use while lowering costs.

Case Histories for this products

SIPA and Wahaha Group: a strong partnership for PET Preform Manufacturing in China

SIPA is proud to highlight its significant collaboration with Wahaha Group, a leading force in China's dynamic beverage industry. This strategic partnership underscores SIPA's commitment to...

SIPA and Arma Food: a collaborative approach to edible oil packaging in Egypt

The long-standing cooperation between SIPA and Arma Food is built on a shared commitment to quality and market-driven innovation.

Corporación AZENDE of Ecuador Boosts Production with SIPA Sincro Bloc Technology

Corporación AZENDE of Ecuador Boosts Production with SIPA Sincro Bloc Technology

Driving Innovation and Efficiency in PET Packaging

07

/

11

/

2025

Driving Innovation and Efficiency in PET Packaging

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

Driving Innovation and Efficiency in PET Packaging

07

/

11

/

2025

Driving Innovation and Efficiency in PET Packaging

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

SIPA and Sarl Noua: A Winning Partnership for the Algerian Beverage Market

Sarl Noua partners with SIPA to launch premium, sustainable mineral water, featuring innovative bottle design and high-speed production capabilities.

17

/

02

/

2026

SIPA and Wahaha Group: a strong partnership for PET Preform Manufacturing in China

SIPA is proud to highlight its significant collaboration with Wahaha Group, a leading force in China's dynamic beverage industry. This strategic partnership underscores SIPA's commitment to...

14

/

01

/

2026

SIPA and Arma Food: a collaborative approach to edible oil packaging in Egypt

The long-standing cooperation between SIPA and Arma Food is built on a shared commitment to quality and market-driven innovation.

10

/

12

/

2025

Corporación AZENDE of Ecuador Boosts Production with SIPA Sincro Bloc Technology

Corporación AZENDE of Ecuador Boosts Production with SIPA Sincro Bloc Technology

07

/

11

/

2025

Driving Innovation and Efficiency in PET Packaging

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

07

/

11

/

2025

Driving Innovation and Efficiency in PET Packaging

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

01

/

10

/

2025

SIPA and Sarl Noua: A Winning Partnership for the Algerian Beverage Market

Sarl Noua partners with SIPA to launch premium, sustainable mineral water, featuring innovative bottle design and high-speed production capabilities.