Materials

- Bottles from 0,125 to 3000 ml

Type

-

The filling machine has been designed for filling glass, PET and refPET bottles

Output

- Fillers from 20 to 100 valves

- Up to 50,000 b/h

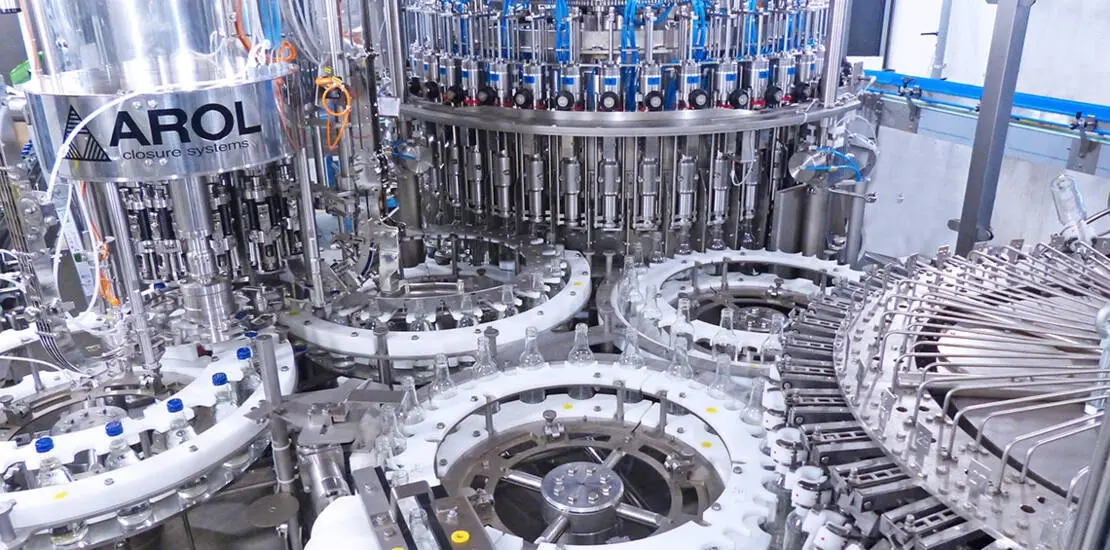

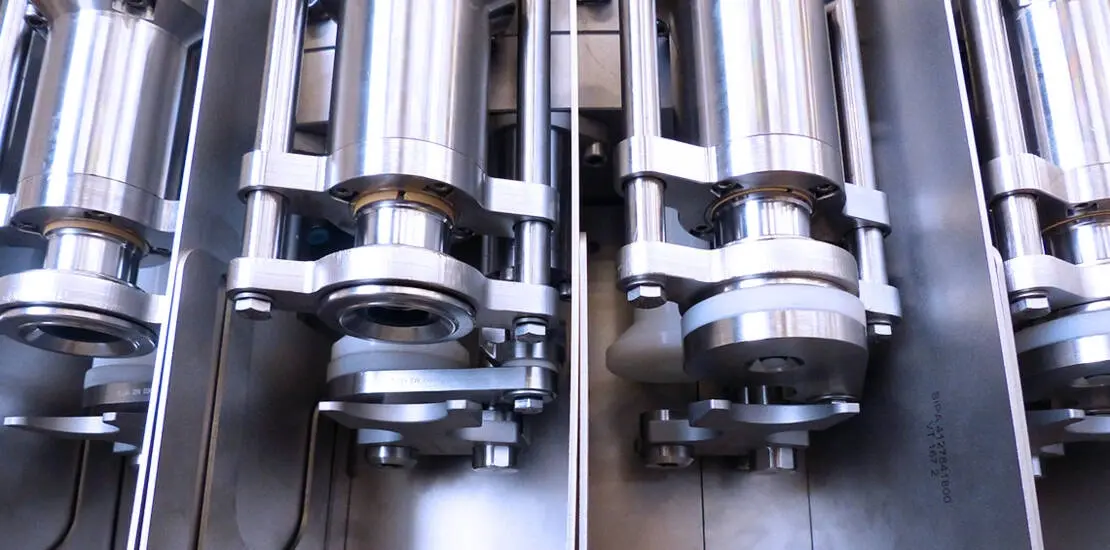

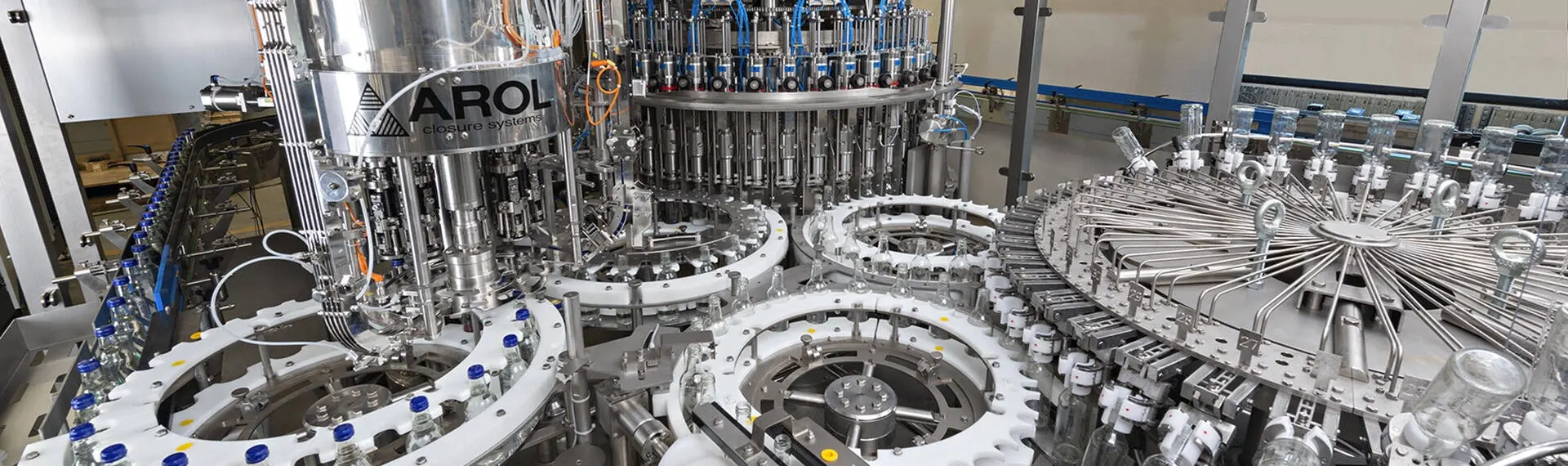

Isotronic G filling monobloc is the perfect solution for companies handling a mix of bottle types. Not only can it fill single-use and refillable (RefPET) PET bottles, but it also works with glass bottles. It can handle bottles using screw tops and crown tops. And can fill with all sorts of still and carbonated drinks.

This isobaric electro-pneumatic level filler has numerous innovative design features to guarantee significant advantages in terms of performance and operating flexibility. It is available in versions with between 20 and 100 valves, with output rates of up to 50,000 bottles per hour.

The filling machine has been designed for filling glass, PET and refPET bottles

The main products that can be processed are: carbonated mineral water and CSD, still water and juices.

Check out the Isotronic G filling system, combining state-of-the-art technology with flexibility for differnt type of bottles. Discover its capabilities

Discover the StillFill Evo, engineered for high-performance filling of still beverages. Learn how it can improve your bottling process

Learn about the Isofill system, designed for carbonated product filling in high-demand industries. Explore the features and benefits for your sector

Discover the BigFill system, tailored for filling large containers with accuracy and speed. See how it can enhance your production line

Explore the Flextronic filling systems by SIPA Solutions, offering versatile, high-precision filling for various bottle types. Find out more

SIPA has officially launched SIPA Additive, a new service designed to provide customers with a fast and cost-effective solution for packaging development. Located at the SIPA HQ Plant, the dedicated...

While high-performance machinery is the backbone of PET production, the future of manufacturing lies in the data hidden within the mold. SIPA is proud to introduce XBrain, an advanced telemetric and...

Celebrating our sustainability achievements: SIPA earns Gold Medal from Ecovadis With an overall score of 78/100 SIPA has been awarded a Gold medal from EcoVadis Sustainability Rating placing us...

SIPA's XFORM RENEW wins Sustainability Awards 2025 for its efficient PET recycling tech, reducing CO₂ emissions and energy use while lowering costs.

SIPA's XFORM RENEW wins Sustainability Awards 2025 for its efficient PET recycling tech, reducing CO₂ emissions and energy use while lowering costs.

SIPA has officially launched SIPA Additive, a new service designed to provide customers with a fast and cost-effective solution for packaging development. Located at the SIPA HQ Plant, the dedicated...

While high-performance machinery is the backbone of PET production, the future of manufacturing lies in the data hidden within the mold. SIPA is proud to introduce XBrain, an advanced telemetric and...

Celebrating our sustainability achievements: SIPA earns Gold Medal from Ecovadis With an overall score of 78/100 SIPA has been awarded a Gold medal from EcoVadis Sustainability Rating placing us...

SIPA's XFORM RENEW wins Sustainability Awards 2025 for its efficient PET recycling tech, reducing CO₂ emissions and energy use while lowering costs.

SIPA's XFORM RENEW wins Sustainability Awards 2025 for its efficient PET recycling tech, reducing CO₂ emissions and energy use while lowering costs.

SIPA is proud to highlight its significant collaboration with Wahaha Group, a leading force in China's dynamic beverage industry. This strategic partnership underscores SIPA's commitment to...

The long-standing cooperation between SIPA and Arma Food is built on a shared commitment to quality and market-driven innovation.

Corporación AZENDE of Ecuador Boosts Production with SIPA Sincro Bloc Technology

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

Sarl Noua partners with SIPA to launch premium, sustainable mineral water, featuring innovative bottle design and high-speed production capabilities.

SIPA is proud to highlight its significant collaboration with Wahaha Group, a leading force in China's dynamic beverage industry. This strategic partnership underscores SIPA's commitment to...

The long-standing cooperation between SIPA and Arma Food is built on a shared commitment to quality and market-driven innovation.

Corporación AZENDE of Ecuador Boosts Production with SIPA Sincro Bloc Technology

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

Sarl Noua partners with SIPA to launch premium, sustainable mineral water, featuring innovative bottle design and high-speed production capabilities.

Please let us know how we can assist you. We have dedicated contact forms for specific inquiries, ensuring your request reaches the right department for a swift and accurate response.

Drinktec | 2025