- Home / Design

- SIPA

Make your brand stand out on the shelf

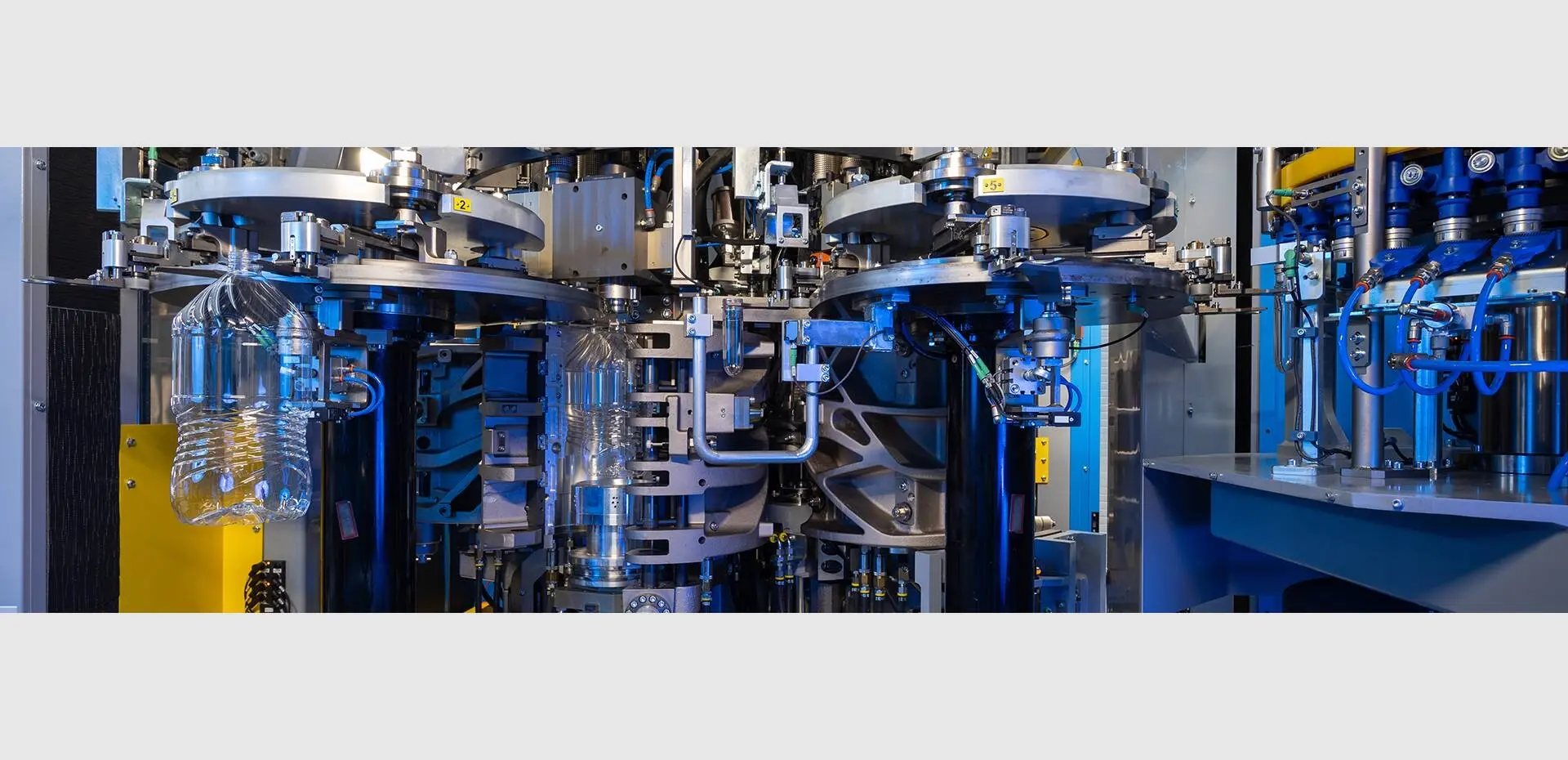

SIPA doesn't just design bottles; we engineer complete packaging ecosystems that elevate your brand and make it stand out on the shelf. With four decades of expertise in PET container machinery manufacturing, we possess an unmatched expertise in combining container design with performance. This allows us to transform your packaging vision into a market-ready reality.

.webp)

Your One-Stop-Shop Packaging Solution

/

01

Our in-house design studio seamlessly blends design and engineering to create holistic packaging solutions. We address every aspect of your packaging journey, from strategic analysis and brand-aligned bottle concepts to custom preform development, prototyping, lab testing, mold production, and line start-up.

Why choose SIPA?

/

02

Holistic Expertise: As the world's only company with a complete portfolio of PET technologies, we offer comprehensive solutions.

Tailored Solutions: We take a consultative approach to understand your unique challenges and develop customized solutions.

Flexible Engagement: Choose from comprehensive design services, technical consultation, or industrialization of your existing concept.

Brand-Centric Design: Our packaging not only protects your product but also communicates your brand story.

Sustainability Focus: Our AWArPET brand reflects our commitment to circularity and reducing environmental impact.

Feasible Design: where creativity meets functionality

/

03

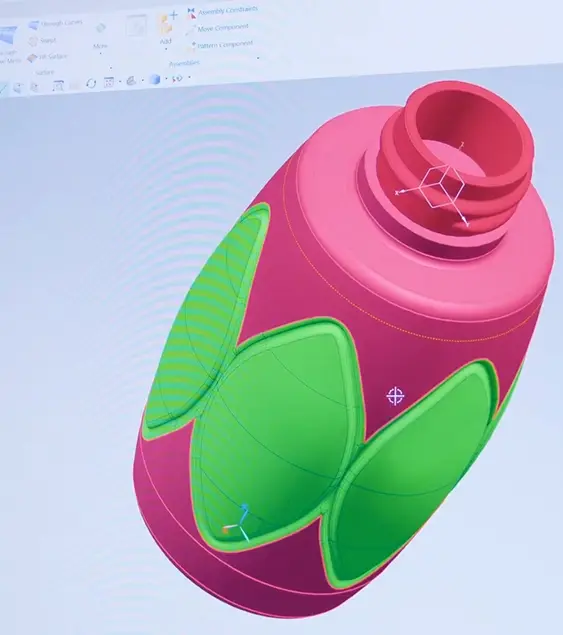

In an era where sustainability is paramount, our Design Center integrates brand aesthetics and values with the production realities of each customer. We offer 360-degree solutions, from brand positioning to container and label design to overpack projects.

Our multidisciplinary team works alongside you at every stage, from brainstorming and sketching to label development, branding, 3D printing, and in-house container prototyping. We call our approach "feasible design" because we prioritize practicality from the very first concept.

This approach is made possible by collaboration between our design team, process engineers, and preform injection experts. We believe that creativity and feasibility must work hand in hand to deliver successful packaging solutions.

1 An optional caption for the image that will be added to the gallery. Enter any descriptive text for this image that you would like visitors to be able to read.

2 An optional caption for the image that will be added to the gallery. Enter any descriptive text for this image that you would like visitors to be able to read.

3 An optional caption for the image that will be added to the gallery. Enter any descriptive text for this image that you would like visitors to be able to read.

4 An optional caption for the image that will be added to the gallery. Enter any descriptive text for this image that you would like visitors to be able to read.

5 An optional caption for the image that will be added to the gallery. Enter any descriptive text for this image that you would like visitors to be able to read.

-

Discover more/02

- SIPA

Discover the other sections of Packaging Solutions

Explore our comprehensive range of packaging services: from initial design and engineering to prototyping containers that bring your unique packaging vision to life.

Innovation

07

/

08

/

2025

Innovation

Our state-of-the-art laboratory facilities offer a complete suite of tests for preforms, containers (including jars, handled containers, and beer kegs), caps, closures, handles, and the diverse materials they comprise.

Validation

27

/

06

/

2025

Validation

Our state-of-the-art laboratory facilities offer a complete suite of tests for preforms, containers (including jars, handled containers, and beer kegs), caps, closures, handles, and the diverse materials they comprise.

Prototyping

27

/

06

/

2025

Prototyping

SIPA offers efficient preform and bottle prototyping, enabling you to quickly evaluate your packaging concepts. Our dedicated team of experts, utilizing a 10,000 square meter facility housing 12 machines (including preform injection, single-stage, and blow molding systems), ensures prototypes that accurately represent your final product.

Packaging engineering

27

/

06

/

2025

Packaging engineering

At SIPA, we craft packaging solutions that not only catch the eye on the shelf but also perform great. Our team works closely with you to understand your specific technical needs and goals, then tailors solutions to optimize performance while considering factors like weight reduction, the use of recycled materials, or alternative materials to PET.

Design

26

/

06

/

2025

Design

SIPA doesn't just design bottles; we engineer complete packaging ecosystems that elevate your brand and make it stand out on the shelf. With four decades of expertise in PET container machinery manufacturing, we possess an unmatched expertise in combining container design with performance.

News for this products

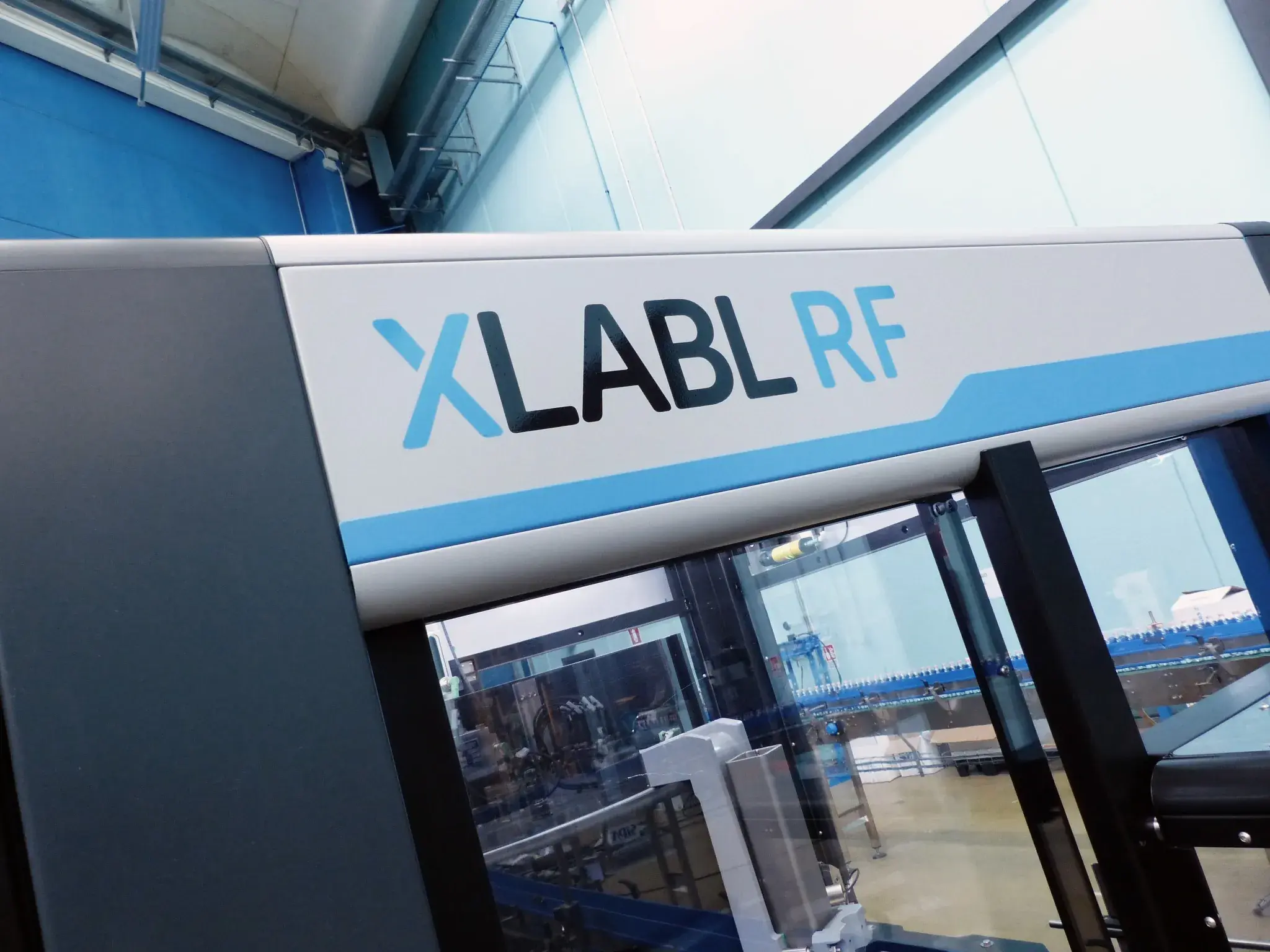

Introducing XLABL RF: New Frontier in Roll-Fed Labelling Technology

Discover SIPA's XLABL_RF, the cutting-edge roll-fed labelling machine that offers precision, flexibility, and efficiency for PET containers.

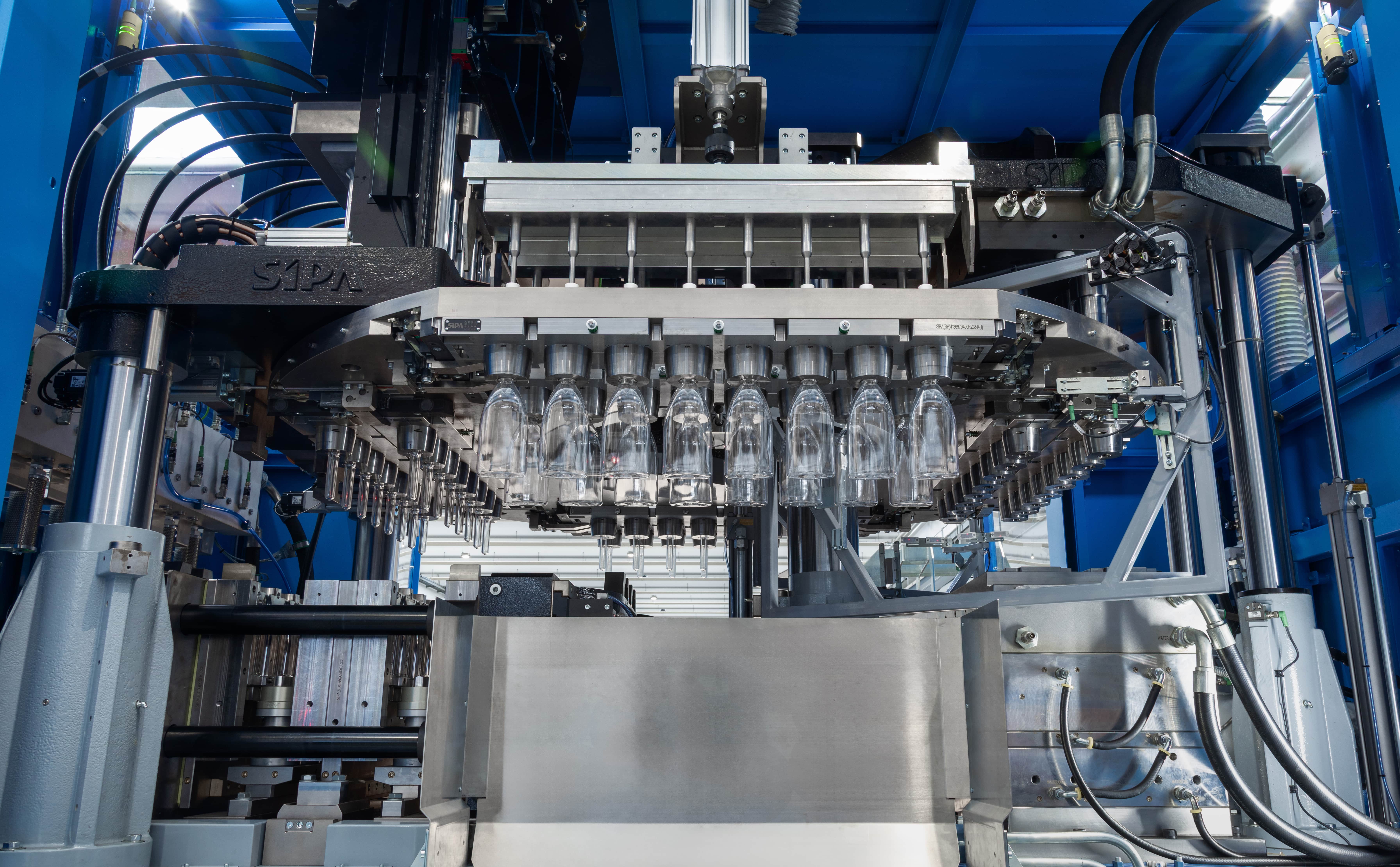

SIPA Redefines ISBM Technology with ECS SP130

01

/

10

/

2025

SIPA Redefines ISBM Technology with ECS SP130

The revolutionary SIPA ECS SP130 ISBM machine, engineered in Italy to set new standards in productivity, quality, and flexibility for packaging production.

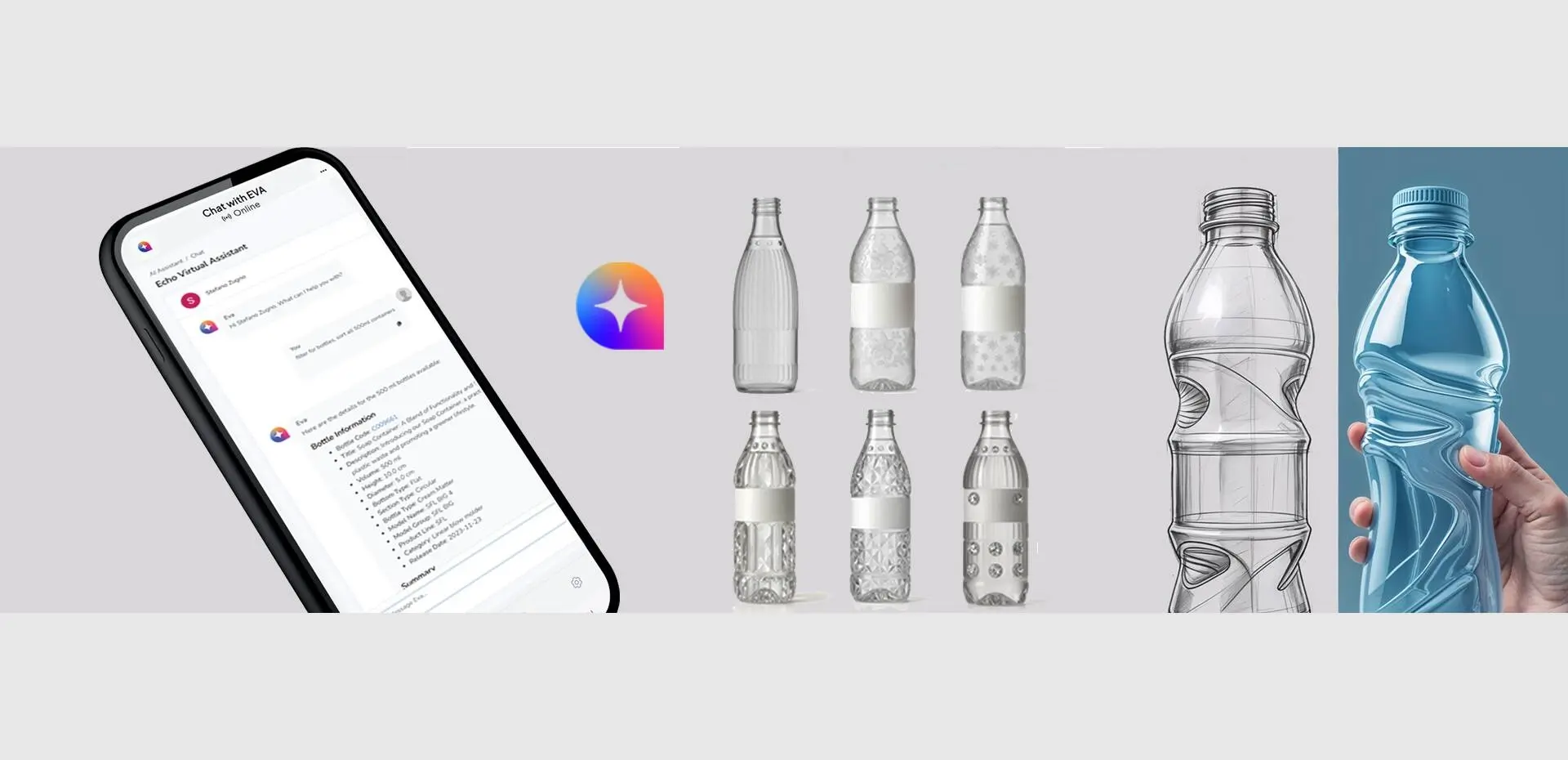

SIPA Leads the Way with Proprietary AI Platform: EVA Redefines Packaging Development

Artificial Intelligence is reshaping the packaging world, unlocking rapid concept generation and previously unthinkable creative possibilities. But while AI can create countless virtual container...

SIPA Streamlines Technical Support with New 24/7 Single Number

SIPA is pleased to announce the successful implementation of its enhanced Remote Technical Support Service, now operating 24 hours a day, 7 days a week, since its launch in March 2025. This...

Seamless Integration and Enhanced Flexibility: Leveraging SIPA ECS SP with Simplified Adaptation kit

22

/

04

/

2025

Seamless Integration and Enhanced Flexibility: Leveraging SIPA ECS SP with Simplified Adaptation kit

Meeting Industry DemandsIn today's dynamic packaging landscape, manufacturers demand agility and efficiency in their production processes. Recognizing this need

Robby Rack: Advanced Robotic Handling for Large Containers

27

/

02

/

2025

Robby Rack: Advanced Robotic Handling for Large Containers

In the packaging market, SIPA is one of the few companies offering a complete range of solutions for large containers up to 5 gallons such as design, engineer

How to enhance affordability and sustainability in large PET Bottles production

SIPA's Research & Development team has engineered a groundbreaking large-format PET mineral water bottle that offers significant cost savings and environmen

ECS SP: the solution for high-quality hot-fillable ketchup containers production

In the competitive food packaging industry, the ability to produce high-quality containers that meet stringent safety and performance standards is paramount. SI

XTRA BIG: High-Output Production of Large-Sized Bottles

04

/

09

/

2024

XTRA BIG: High-Output Production of Large-Sized Bottles

XTRA BIG rotary stretch-blow molding machines are engineered to produce large, symmetric bottles with capacities up to 12 liters.

SIPA launches Ultralight, High-Performance GME 30.40 LW Neck Finish

SIPA has unveiled a groundbreaking innovation in carbonated soft drink (CSD) – the GME 30.40 LW neck finish. Weighing a mere 2.04 grams, this lightweight powerhouse is set to redefine industry...

SIPA Celebrates in Bangkok the double win for La Spumante at WORLDSTAR 2024 Packaging Awards

20

/

06

/

2024

SIPA Celebrates in Bangkok the double win for La Spumante at WORLDSTAR 2024 Packaging Awards

Bangkok, Thailand June 15, 2024 In a remarkable achievement, SIPA's innovative La Spumante PET bottle for sparkling wine has secured two prestig

Zoppas Industries expands employee welfare initiative

13

/

06

/

2024

Zoppas Industries expands employee welfare initiative

The Zoppas Industries Group (which includes IRCA S.p.A Zoppas Industries Heating Element Technolog

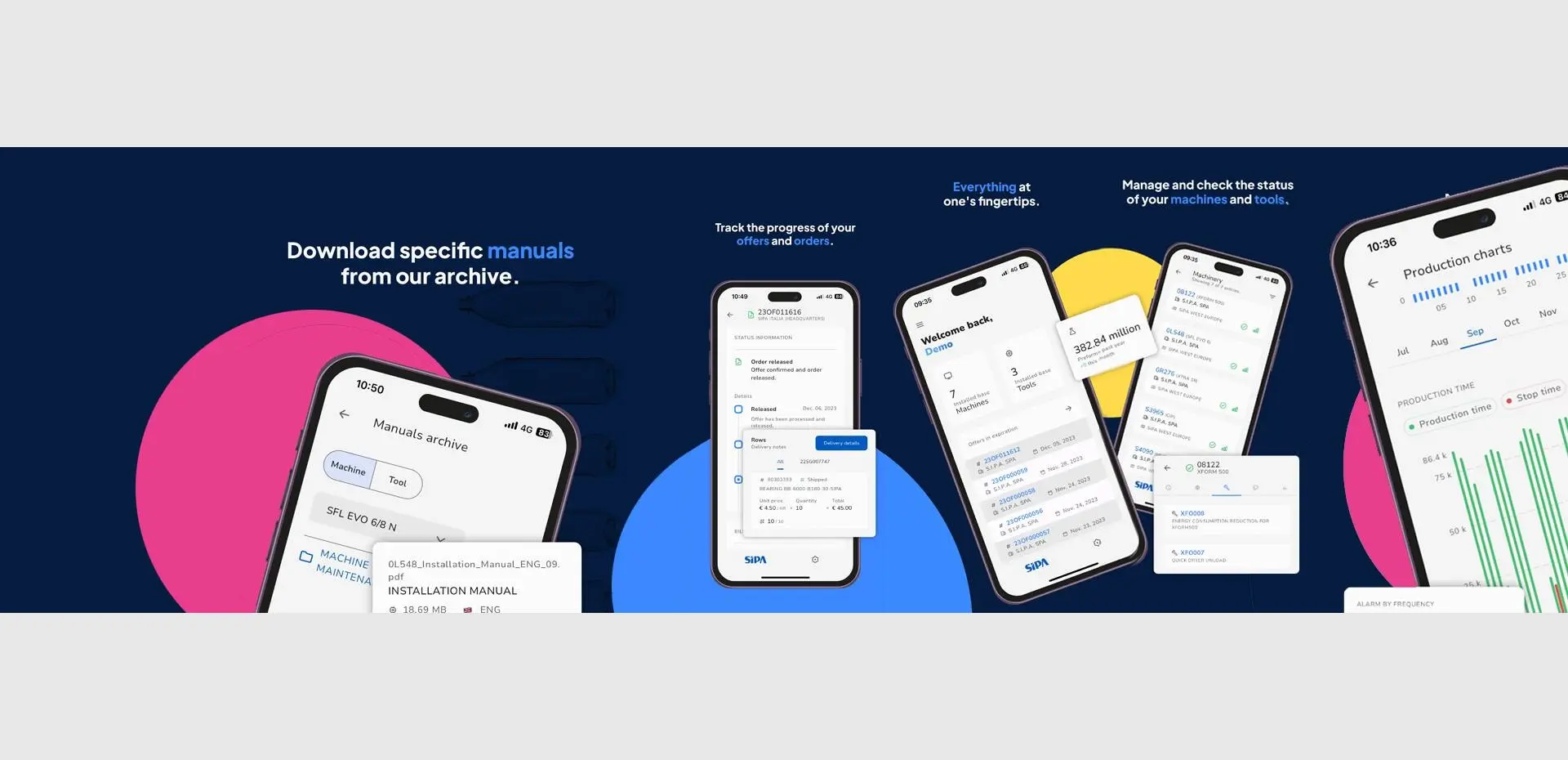

Echo Mobile: The ultimate mobile app for enhanced productivity and connectivity

We are thrilled to announce the launch of the Echo mobile application for both Android and iOS devices! This exciting new app brings all the features you love f

What's on at NPE 2024, Orlando | booth #S19096

11

/

04

/

2024

What's on at NPE 2024, Orlando | booth #S19096

Challenging packaging to prove our innovative design and technology capabilities. On show: At SIPA's booth you will experience our comprehensive 360deg

SIPA shows strength in refillable PET bottle blowing

05

/

03

/

2024

SIPA shows strength in refillable PET bottle blowing

The popularity of refillable PET bottles is growing fast. Governments are pushing for them, all sorts of technologies are increasingly enabling them, major bran

La Spumante shines bright: triumphs at WORLDSTAR 2024

19

/

01

/

2024

La Spumante shines bright: triumphs at WORLDSTAR 2024

In a triumph of innovation and sustainability, SIPA La Spumante, the first PET bottle for sparkling wine, has secured two prestigious accolades at the WORLDSTAR

Your Trusted Partner for Cutting-Edge Cosmetic Packaging Solutions

In the dynamic world of cosmetics and personal care, packaging plays a pivotal role in attracting consumers and ensuring product integrity. Manufacturers in the

07

/

11

/

2025

Introducing XLABL RF: New Frontier in Roll-Fed Labelling Technology

Discover SIPA's XLABL_RF, the cutting-edge roll-fed labelling machine that offers precision, flexibility, and efficiency for PET containers.

01

/

10

/

2025

SIPA Redefines ISBM Technology with ECS SP130

The revolutionary SIPA ECS SP130 ISBM machine, engineered in Italy to set new standards in productivity, quality, and flexibility for packaging production.

09

/

06

/

2025

SIPA Leads the Way with Proprietary AI Platform: EVA Redefines Packaging Development

Artificial Intelligence is reshaping the packaging world, unlocking rapid concept generation and previously unthinkable creative possibilities. But while AI can create countless virtual container...

16

/

05

/

2025

SIPA Streamlines Technical Support with New 24/7 Single Number

SIPA is pleased to announce the successful implementation of its enhanced Remote Technical Support Service, now operating 24 hours a day, 7 days a week, since its launch in March 2025. This...

22

/

04

/

2025

Seamless Integration and Enhanced Flexibility: Leveraging SIPA ECS SP with Simplified Adaptation kit

Meeting Industry DemandsIn today's dynamic packaging landscape, manufacturers demand agility and efficiency in their production processes. Recognizing this need

27

/

02

/

2025

Robby Rack: Advanced Robotic Handling for Large Containers

In the packaging market, SIPA is one of the few companies offering a complete range of solutions for large containers up to 5 gallons such as design, engineer

12

/

12

/

2024

How to enhance affordability and sustainability in large PET Bottles production

SIPA's Research & Development team has engineered a groundbreaking large-format PET mineral water bottle that offers significant cost savings and environmen

31

/

10

/

2024

ECS SP: the solution for high-quality hot-fillable ketchup containers production

In the competitive food packaging industry, the ability to produce high-quality containers that meet stringent safety and performance standards is paramount. SI

04

/

09

/

2024

XTRA BIG: High-Output Production of Large-Sized Bottles

XTRA BIG rotary stretch-blow molding machines are engineered to produce large, symmetric bottles with capacities up to 12 liters.

17

/

07

/

2024

SIPA launches Ultralight, High-Performance GME 30.40 LW Neck Finish

SIPA has unveiled a groundbreaking innovation in carbonated soft drink (CSD) – the GME 30.40 LW neck finish. Weighing a mere 2.04 grams, this lightweight powerhouse is set to redefine industry...

20

/

06

/

2024

SIPA Celebrates in Bangkok the double win for La Spumante at WORLDSTAR 2024 Packaging Awards

Bangkok, Thailand June 15, 2024 In a remarkable achievement, SIPA's innovative La Spumante PET bottle for sparkling wine has secured two prestig

13

/

06

/

2024

Zoppas Industries expands employee welfare initiative

The Zoppas Industries Group (which includes IRCA S.p.A Zoppas Industries Heating Element Technolog

17

/

05

/

2024

Echo Mobile: The ultimate mobile app for enhanced productivity and connectivity

We are thrilled to announce the launch of the Echo mobile application for both Android and iOS devices! This exciting new app brings all the features you love f

11

/

04

/

2024

What's on at NPE 2024, Orlando | booth #S19096

Challenging packaging to prove our innovative design and technology capabilities. On show: At SIPA's booth you will experience our comprehensive 360deg

05

/

03

/

2024

SIPA shows strength in refillable PET bottle blowing

The popularity of refillable PET bottles is growing fast. Governments are pushing for them, all sorts of technologies are increasingly enabling them, major bran

19

/

01

/

2024

La Spumante shines bright: triumphs at WORLDSTAR 2024

In a triumph of innovation and sustainability, SIPA La Spumante, the first PET bottle for sparkling wine, has secured two prestigious accolades at the WORLDSTAR

06

/

11

/

2023

Your Trusted Partner for Cutting-Edge Cosmetic Packaging Solutions

In the dynamic world of cosmetics and personal care, packaging plays a pivotal role in attracting consumers and ensuring product integrity. Manufacturers in the

Case Histories for this products

SIPA and Wahaha Group: a strong partnership for PET Preform Manufacturing in China

SIPA is proud to highlight its significant collaboration with Wahaha Group, a leading force in China's dynamic beverage industry. This strategic partnership underscores SIPA's commitment to...

SIPA and Arma Food: a collaborative approach to edible oil packaging in Egypt

The long-standing cooperation between SIPA and Arma Food is built on a shared commitment to quality and market-driven innovation.

Corporación AZENDE of Ecuador Boosts Production with SIPA Sincro Bloc Technology

Corporación AZENDE of Ecuador Boosts Production with SIPA Sincro Bloc Technology

Driving Innovation and Efficiency in PET Packaging

07

/

11

/

2025

Driving Innovation and Efficiency in PET Packaging

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

Driving Innovation and Efficiency in PET Packaging

07

/

11

/

2025

Driving Innovation and Efficiency in PET Packaging

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

SIPA and Sarl Noua: A Winning Partnership for the Algerian Beverage Market

Sarl Noua partners with SIPA to launch premium, sustainable mineral water, featuring innovative bottle design and high-speed production capabilities.

17

/

02

/

2026

SIPA and Wahaha Group: a strong partnership for PET Preform Manufacturing in China

SIPA is proud to highlight its significant collaboration with Wahaha Group, a leading force in China's dynamic beverage industry. This strategic partnership underscores SIPA's commitment to...

14

/

01

/

2026

SIPA and Arma Food: a collaborative approach to edible oil packaging in Egypt

The long-standing cooperation between SIPA and Arma Food is built on a shared commitment to quality and market-driven innovation.

10

/

12

/

2025

Corporación AZENDE of Ecuador Boosts Production with SIPA Sincro Bloc Technology

Corporación AZENDE of Ecuador Boosts Production with SIPA Sincro Bloc Technology

07

/

11

/

2025

Driving Innovation and Efficiency in PET Packaging

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

07

/

11

/

2025

Driving Innovation and Efficiency in PET Packaging

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

01

/

10

/

2025

SIPA and Sarl Noua: A Winning Partnership for the Algerian Beverage Market

Sarl Noua partners with SIPA to launch premium, sustainable mineral water, featuring innovative bottle design and high-speed production capabilities.