| MODEL | CAPACITY |

| Xblend 12 | Up to 12,000 l/h |

| Xblend 27 | Up to 27,000 l/h |

| Xblend 34 | Up to 34,000 l/h |

| Xblend 42 | Up to 42,000 l/h |

| Xblend 54 | Up to 54,000 l/h |

| Xblend 66 | Up to 66,000 l/h |

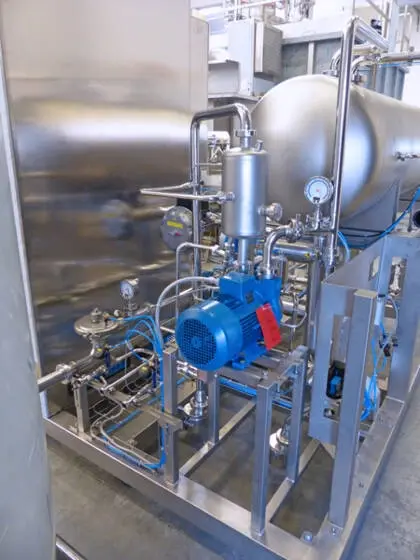

Degassing

The inlet water is deaerated inside a tank by using nozzles, in high vacuum atmosphere (excludable). A magnetic flow meter counts the water that is sent to the mixing system by using a centrifugal pump.

Blending

The inlet syrup is monitored by using a mass flow meter to adjust, if necessary, the dilution ratio in order to maintain and to ensure the maximum accuracy and the maximum repeatability of the final beverage.

A special diffuser is installed to obtain an homogeneous dissolution of the desired syrup quantity, moreover the dispersion of gas is realized through a further static mixer that ensures a fine mixing of the finished beverage.

| MODEL | CAPACITY |

| Xblend 12 | Up to 12,000 l/h |

| Xblend 27 | Up to 27,000 l/h |

| Xblend 34 | Up to 34,000 l/h |

| Xblend 42 | Up to 42,000 l/h |

| Xblend 54 | Up to 54,000 l/h |

| Xblend 66 | Up to 66,000 l/h |

SIPA's XFORM RENEW wins Sustainability Awards 2025 for its efficient PET recycling tech, reducing CO₂ emissions and energy use while lowering costs.

Discover SIPA's XLABL_RF, the cutting-edge roll-fed labelling machine that offers precision, flexibility, and efficiency for PET containers.

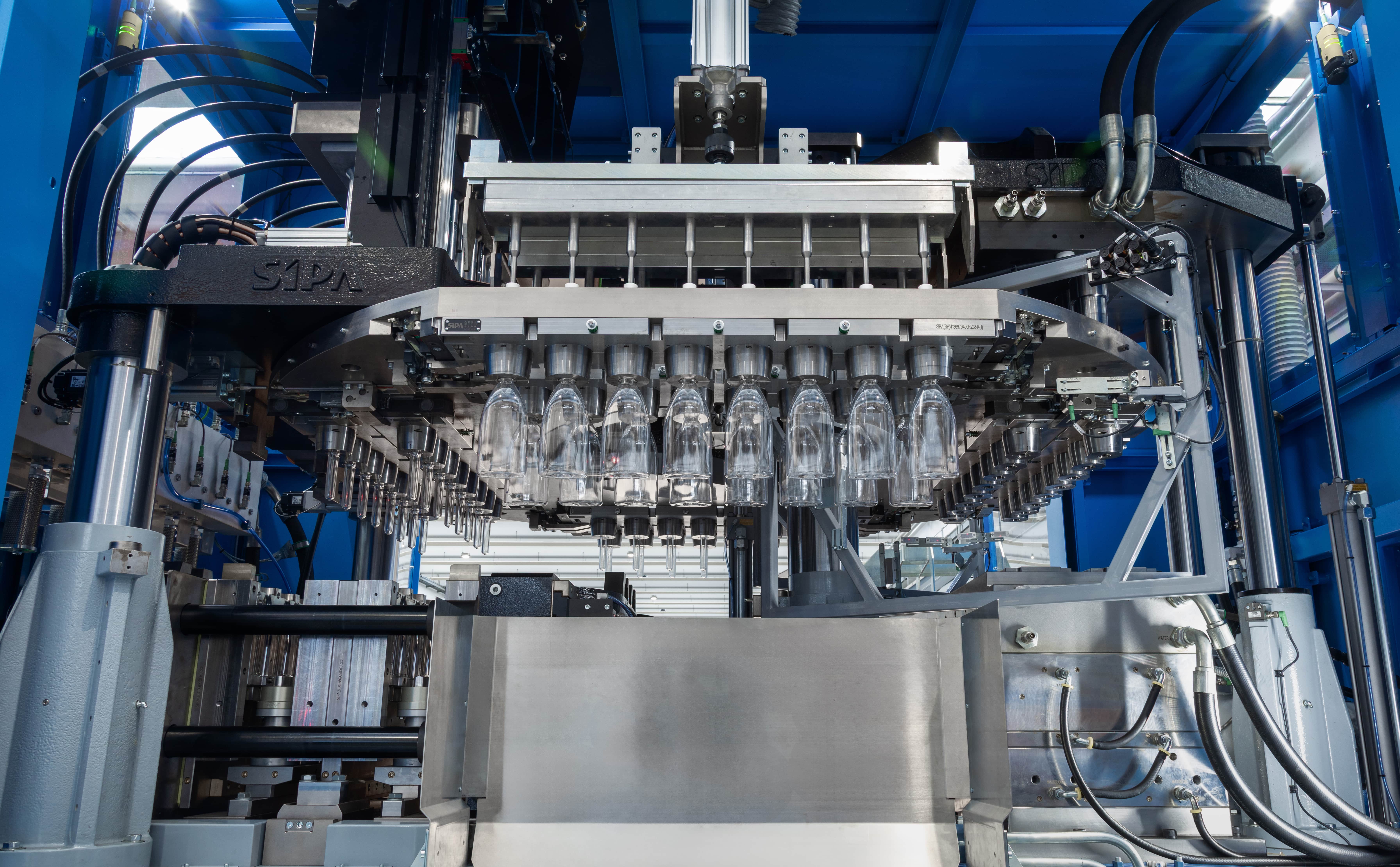

The revolutionary SIPA ECS SP130 ISBM machine, engineered in Italy to set new standards in productivity, quality, and flexibility for packaging production.

Artificial Intelligence is reshaping the packaging world, unlocking rapid concept generation and previously unthinkable creative possibilities. But while AI can create countless virtual container...

SIPA is pleased to announce the successful implementation of its enhanced Remote Technical Support Service, now operating 24 hours a day, 7 days a week, since its launch in March 2025. This...

SIPA's XFORM RENEW wins Sustainability Awards 2025 for its efficient PET recycling tech, reducing CO₂ emissions and energy use while lowering costs.

Discover SIPA's XLABL_RF, the cutting-edge roll-fed labelling machine that offers precision, flexibility, and efficiency for PET containers.

The revolutionary SIPA ECS SP130 ISBM machine, engineered in Italy to set new standards in productivity, quality, and flexibility for packaging production.

Artificial Intelligence is reshaping the packaging world, unlocking rapid concept generation and previously unthinkable creative possibilities. But while AI can create countless virtual container...

SIPA is pleased to announce the successful implementation of its enhanced Remote Technical Support Service, now operating 24 hours a day, 7 days a week, since its launch in March 2025. This...

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

Sarl Noua partners with SIPA to launch premium, sustainable mineral water, featuring innovative bottle design and high-speed production capabilities.

CGM bolsters its market leadership in the beverage industry by acquiring two more SIPA XFORM systems with 200-cavity molds.

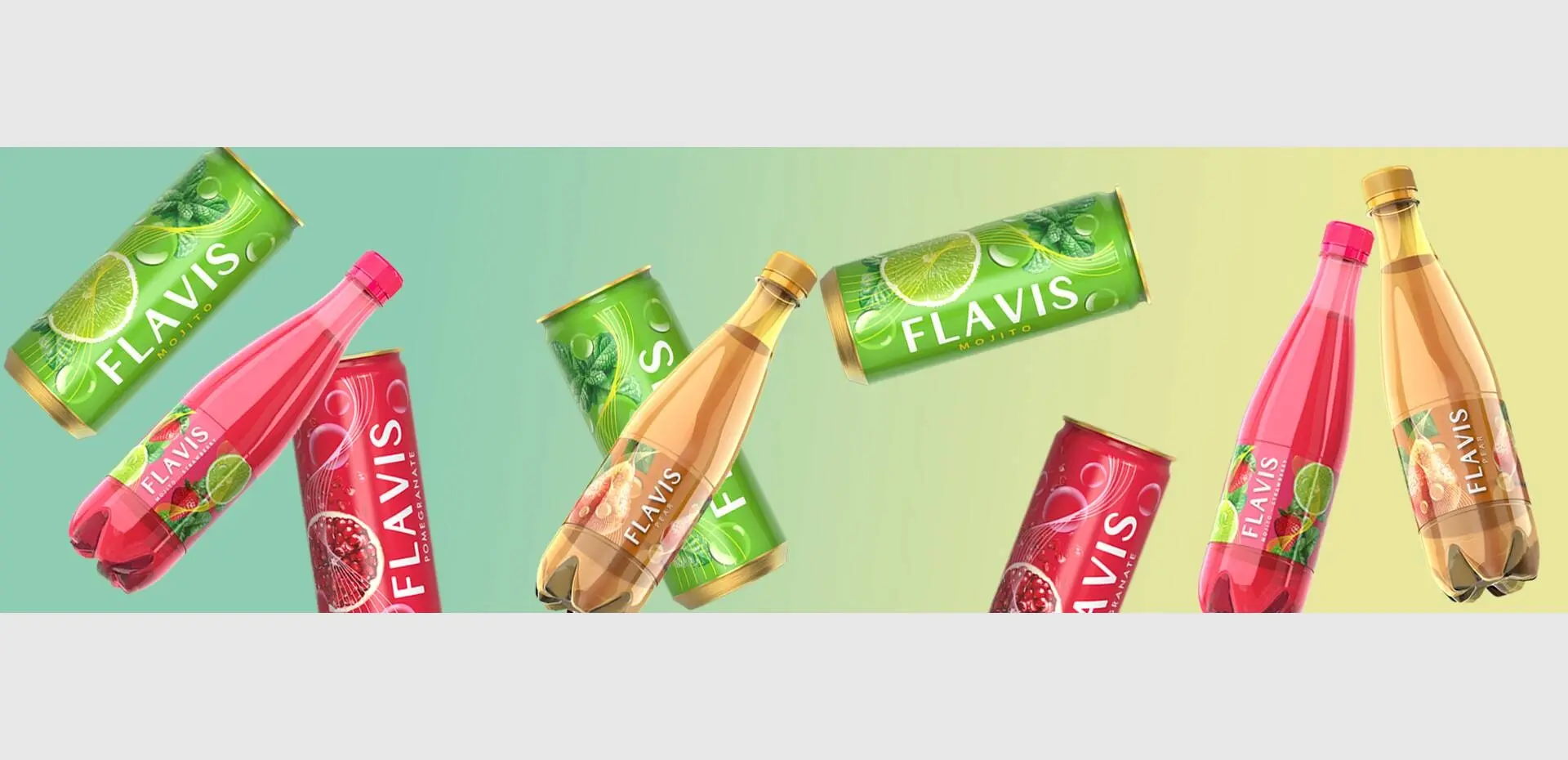

SIPA Packaging Development has secured a significant project with Family Group, a prominent beverage company hailing from Uzbekistan and the owner of

In the fiercely competitive world of beverages, getting things done efficiently, keeping everything super clean, and making your product stand out

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

Sarl Noua partners with SIPA to launch premium, sustainable mineral water, featuring innovative bottle design and high-speed production capabilities.

CGM bolsters its market leadership in the beverage industry by acquiring two more SIPA XFORM systems with 200-cavity molds.

SIPA Packaging Development has secured a significant project with Family Group, a prominent beverage company hailing from Uzbekistan and the owner of

In the fiercely competitive world of beverages, getting things done efficiently, keeping everything super clean, and making your product stand out

Please let us know how we can assist you. We have dedicated contact forms for specific inquiries, ensuring your request reaches the right department for a swift and accurate response.

Drinktec | 2025