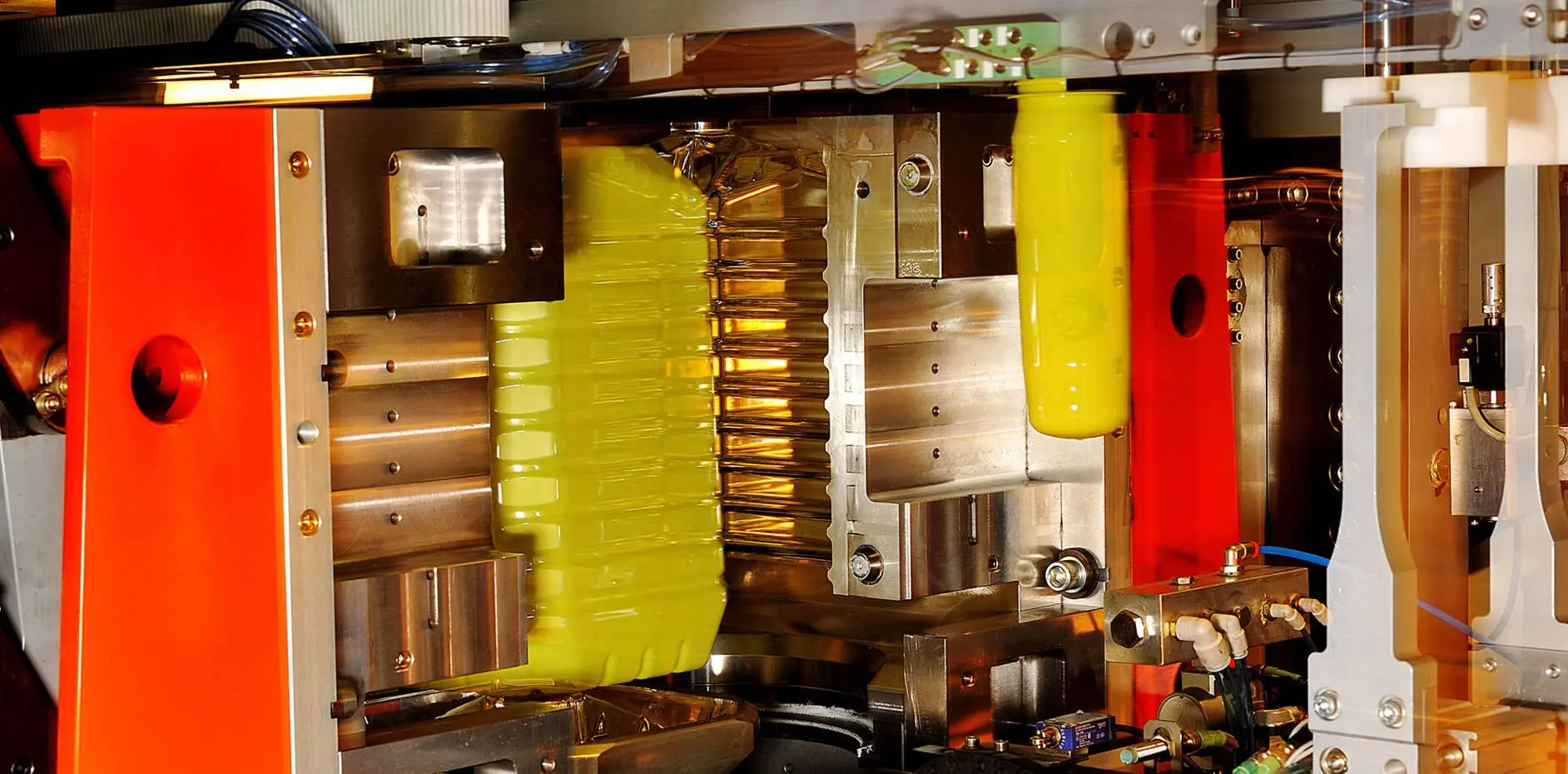

SFL shifts the boundaries in the evolution of linear blowmoulding, offering maximum flexibility combined with increased output. A consolidated technology with the lowest total cost of ownership (TCO) on the market, designed to operate with 1 to 8 blowing cavities and to reach a maximum productivity of 2,000 bottles/hour/cavity, with the lowest ever energy consumption. The reference for the PET packaging market, unmatched in the industry, shows numerous technological developments in terms of speed, quality, versatility, capacity, energy efficiency and overall sustainability. It incorporates highly innovative digital solutions to fit in the most visionary Smart Factory. All these unique features, together with the low maintenance costs, make SFL truly a “best in class” among linear systems.

Contact Us

Contact Us