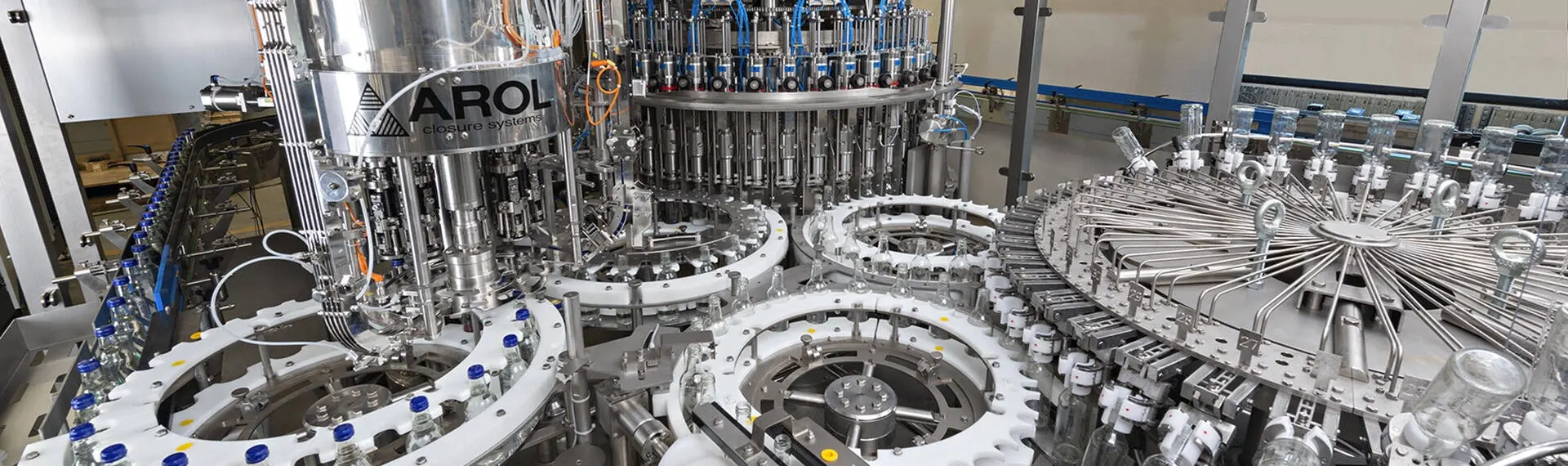

- Central tank, with product feeding form the bottom of the rotating manifold.

- Entirely stainless steel (grade 304) draining base.

- Reliable, simple and easily sanitized valve.

- Reduced changeover down-times.

- "No bottle no fill",, no electronics in the machine.

- PET bottle transfer - neck-handling - with no need for monoblock height adjustment.

- Possibility of installing a level control system.

- User friendly touch screen HMI, with menu-based interface

- Sincro Bloc configuration available, for an integrated blowing- filling-capping solution.

- Controlled contamination cabin, micro isolator and cap sterilizing unit available in option in order to enhance hygienic standards.

This is a modular project with the same features and advantages for both configurations, with the only difference between the S and HR configurations is a simple- hot-fill kit, including:

- a pneumatic valve within the filling valves for product recirculation,

- a rotating manifold for product recirculation,

- an external tank for recovery of the recycled product and pumping back to the pasteurizer.

Contact Us

Contact Us