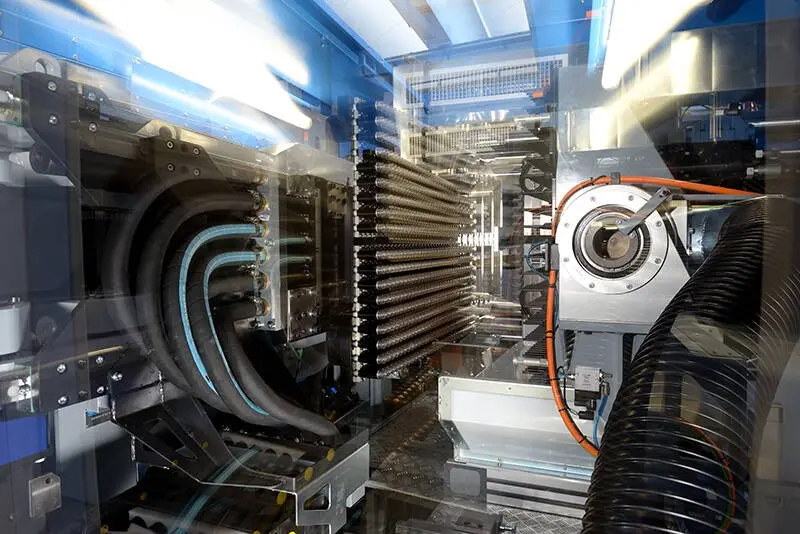

Materials

- PET

- OPP

- PLA

- rPET

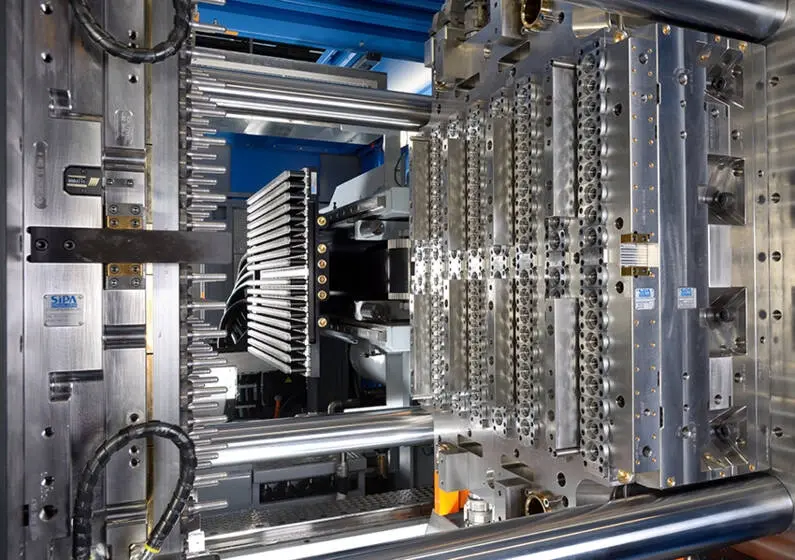

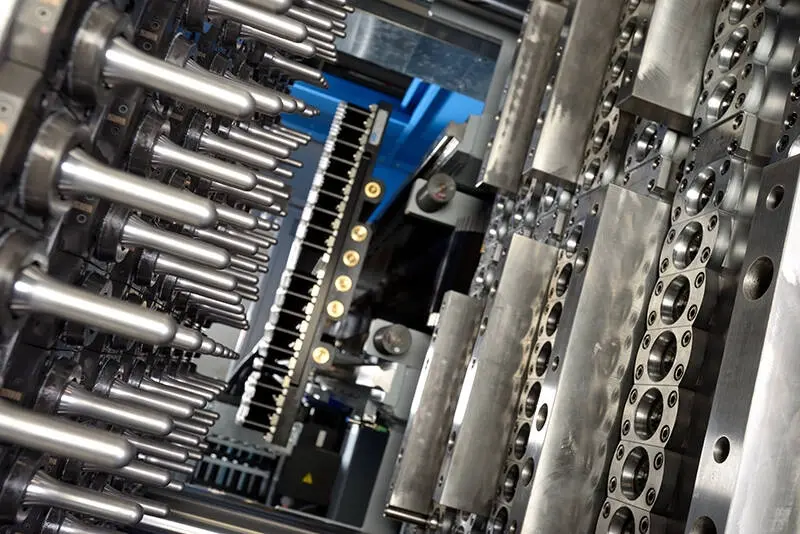

Type

- Thin-wall preforms(for lightweight bottles for mineral water, edible oil)

- Thick-wall preforms (for carbonated beverages)

- Preforms for heat set bottles

- Wide mouth preforms for jars

- Long preforms for large size containers

Productivity table

| MODEL |

CAVITATION (MIN-MAX) |

MAX OUTPUT (p/h) |

PREFORM THREAD (MIN-MAX) |

STD MAX PREFORM LENGTH* |

| XFORM 500 | 24-200 | up to 160,000 | 28-80 mm | 250 mm |

| XFORM 350 | 16-128 | up to 102,400 | 30-80 mm | 250 mm |

| XFORM 250 | 8-96 | up to 76,800 | 30-80 mm | 250 mm |

| XFORM 160 | 2-60 | UP TO 28,800 | 29-140 mm | 250 mm |

*With special machine execution, longer preforms are feasible

Contact Us

Contact Us