Materials

- PET

- Recycled PET

- rPET flakes

Type

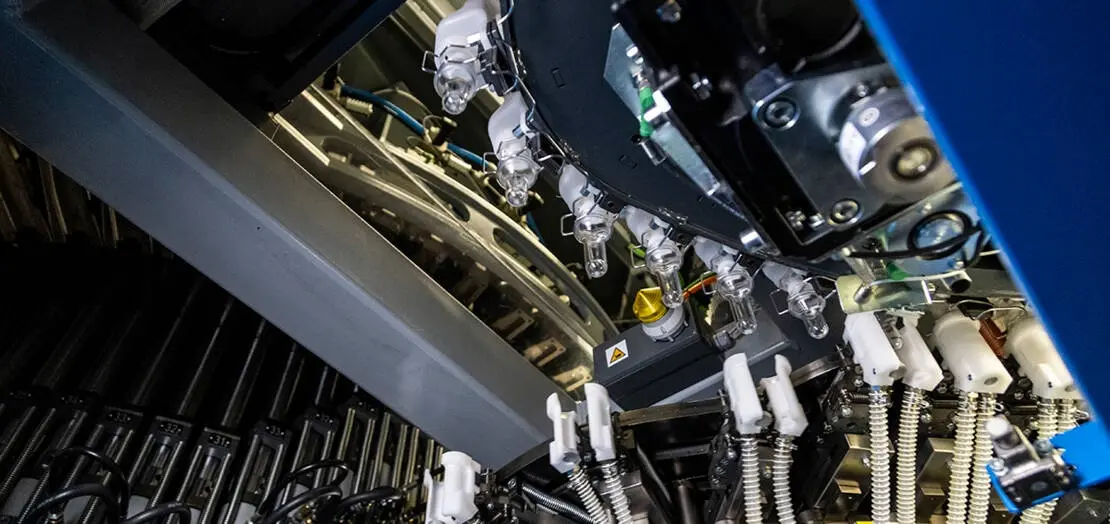

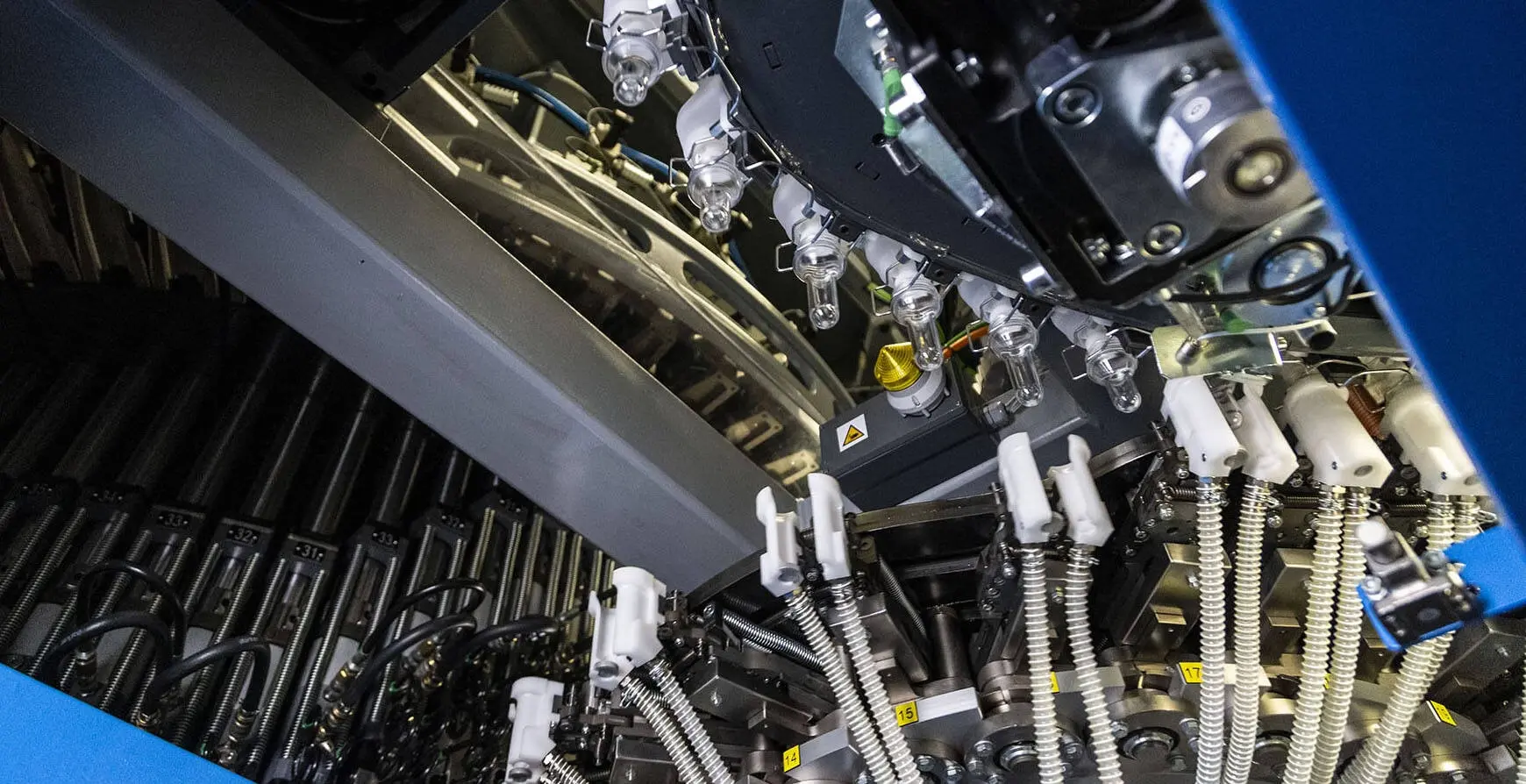

- Extreme lightweight

- Preform revolutionary design: longer preforms with very thin thickness

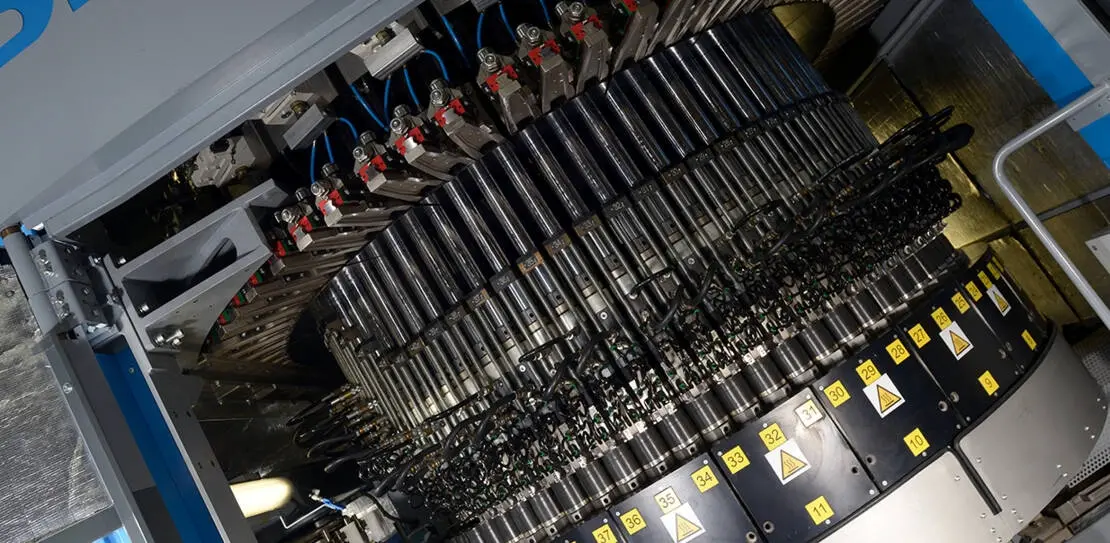

| MODEL | CAVITATION | MAX OUTPUT (P/HOUR) | MIN PREFORM BASE THICKNESS (mm) | MAX PREFORM WEIGHT (g) | MAX PREFORM LENGHT (mm) |

| XTREME | 96 | up to 70,000 | 0.95 | 60 | 150 |

| XTREME | 72 | up to 57,600 | 0.95 | 60 | 150 |

Contact Us

Contact Us