- Home / Ingegnerizzazione del packaging

- SIPA

Rendete più performante il vostro packaging

Noi di SIPA creiamo soluzioni di packaging che non solo catturano l'attenzione sullo scaffale, ma offrono anche grandi prestazioni. Il nostro team lavora a stretto contatto con voi per comprendere le vostre specifiche esigenze e obiettivi tecnici, e personalizza le soluzioni per ottimizzare le prestazioni, tenendo in considerazione fattori come la riduzione del peso, l'uso di materiali riciclati o materiali alternativi al PET.

Design Ottimale, Massime Prestazioni

/

01

Diamo priorità all'ottimizzazione della geometria nella progettazione dei nostri preformati e contenitori, bilanciando proprietà dei materiali, peso e requisiti applicativi. Questo si traduce in un imballaggio leggero ma resistente che riduce i costi, aumenta la sostenibilità e semplifica la logistica.

La nostra esperienza ingegneristica va oltre la semplice riduzione del peso: ottimizziamo meticolosamente ogni contenitore per una perfetta integrazione con l'intera linea di produzione, dal riempimento alla pallettizzazione.

La nostra esperienza ingegneristica va oltre la semplice riduzione del peso: ottimizziamo meticolosamente ogni contenitore per una perfetta integrazione con l'intera linea di produzione, dal riempimento alla pallettizzazione.

Prototipazione Virtuale per Risultati Concreti

/

02

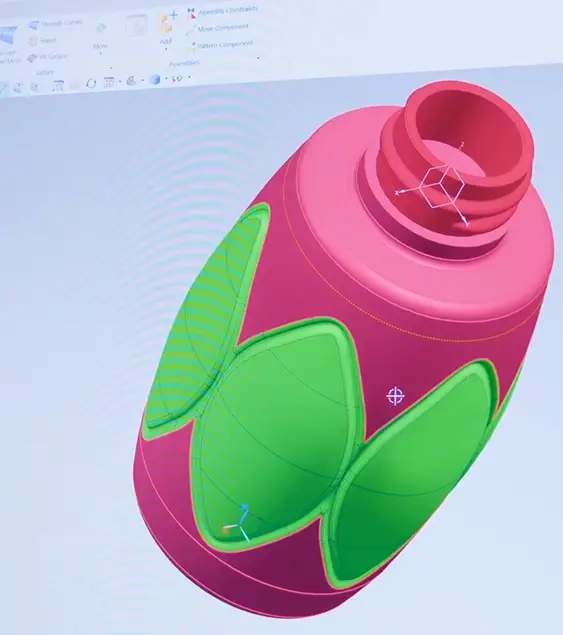

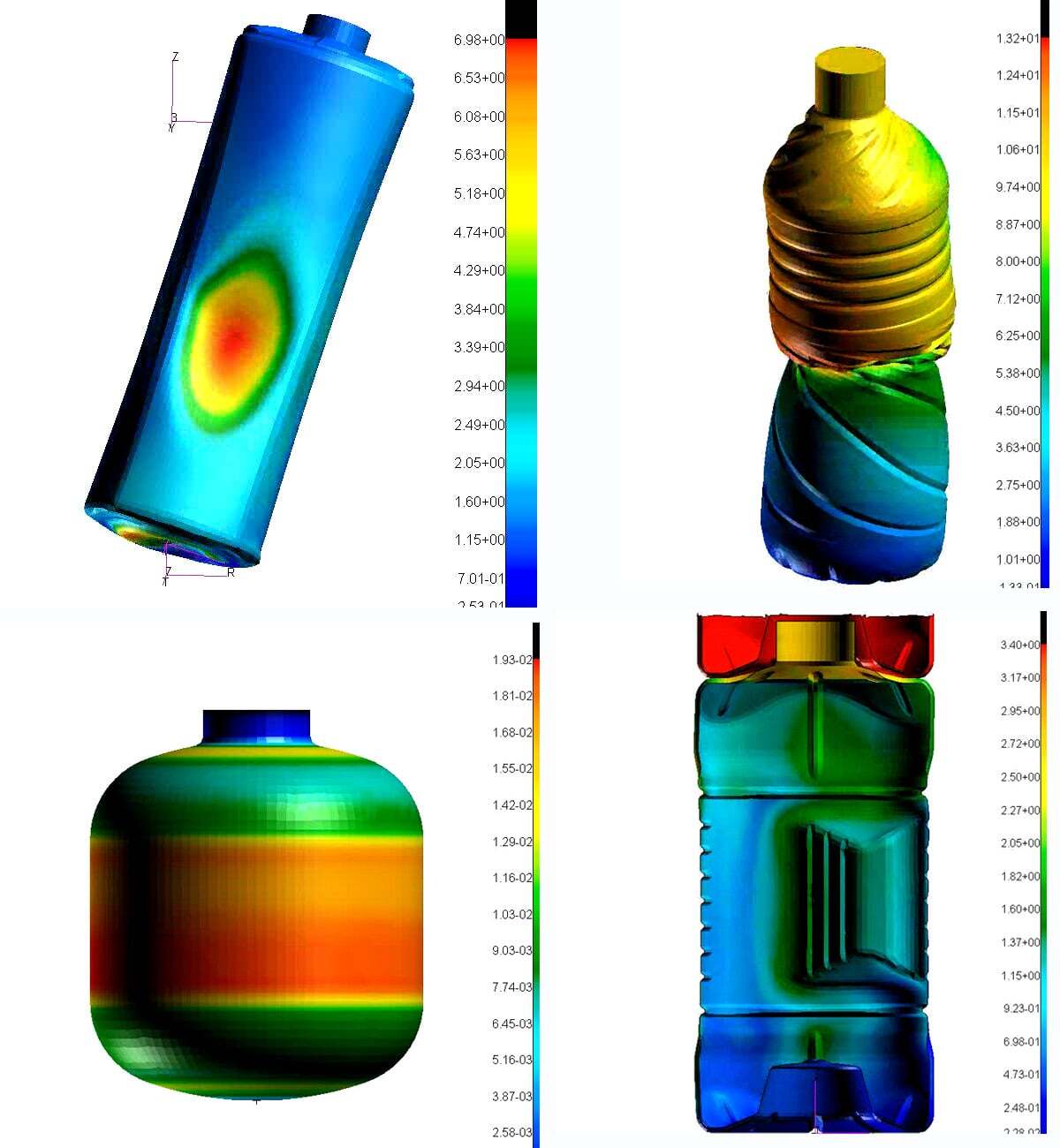

Sfruttando tecnologie all'avanguardia come il digital twin e l'analisi agli elementi finiti (FEA), creiamo modelli virtuali che predicono con precisione le prestazioni reali dei contenitori in diverse condizioni. Questo ci permette di ottimizzare i design e identificare potenziali problemi prima di passare alla prototipazione fisica, facendoti risparmiare tempo e risorse.

Ottimizzazione a Ogni Livello

/

03

La nostra metodologia ti consente di lanciare con sicurezza nuove forme di imballaggio o di ridurre i costi senza sacrificare le prestazioni. Ottimizziamo meticolosamente ogni aspetto del tuo packaging, dalla scelta dei materiali ai processi di produzione, garantendo un perfetto equilibrio tra performance ed economicità.

Integrazione Olistica della Linea di Imbottigliamento

/

04

Progettiamo il tuo packaging tenendo a mente l'intera linea di imbottigliamento, considerando i requisiti specifici di riempimento, tappatura, convogliamento e pallettizzazione. Questo approccio olistico garantisce un'integrazione perfetta e un'efficienza ottimale lungo tutto il tuo processo produttivo.

1 An optional caption for the image that will be added to the gallery. Enter any descriptive text for this image that you would like visitors to be able to read.

2 An optional caption for the image that will be added to the gallery. Enter any descriptive text for this image that you would like visitors to be able to read.

3 An optional caption for the image that will be added to the gallery. Enter any descriptive text for this image that you would like visitors to be able to read.

4 An optional caption for the image that will be added to the gallery. Enter any descriptive text for this image that you would like visitors to be able to read.

5 An optional caption for the image that will be added to the gallery. Enter any descriptive text for this image that you would like visitors to be able to read.

-

Scopri di più/02

- SIPA

Scopri le altre sezioni di Soluzioni di Packaging.

Esplora la nostra gamma completa di servizi di packaging: dalla progettazione iniziale e ingegneria alla prototipazione di contenitori che danno vita alla tua visione unica di packaging.

Innovazione

01

/

11

/

2025

Innovazione

I nostri laboratori all'avanguardia offrono una suite completa di test per preforme, contenitori (inclusi vasetti, contenitori con maniglia e fusti di birra), tappi, chiusure, maniglie e i diversi materiali di cui sono composti.

Laboratorio Qualità

31

/

10

/

2025

Laboratorio Qualità

I nostri laboratori all'avanguardia offrono una suite completa di test per preforme, contenitori (inclusi vasetti, contenitori con maniglia e fusti di birra), tappi, chiusure, maniglie e i diversi materiali di cui sono composti.

Prototipazione

30

/

10

/

2025

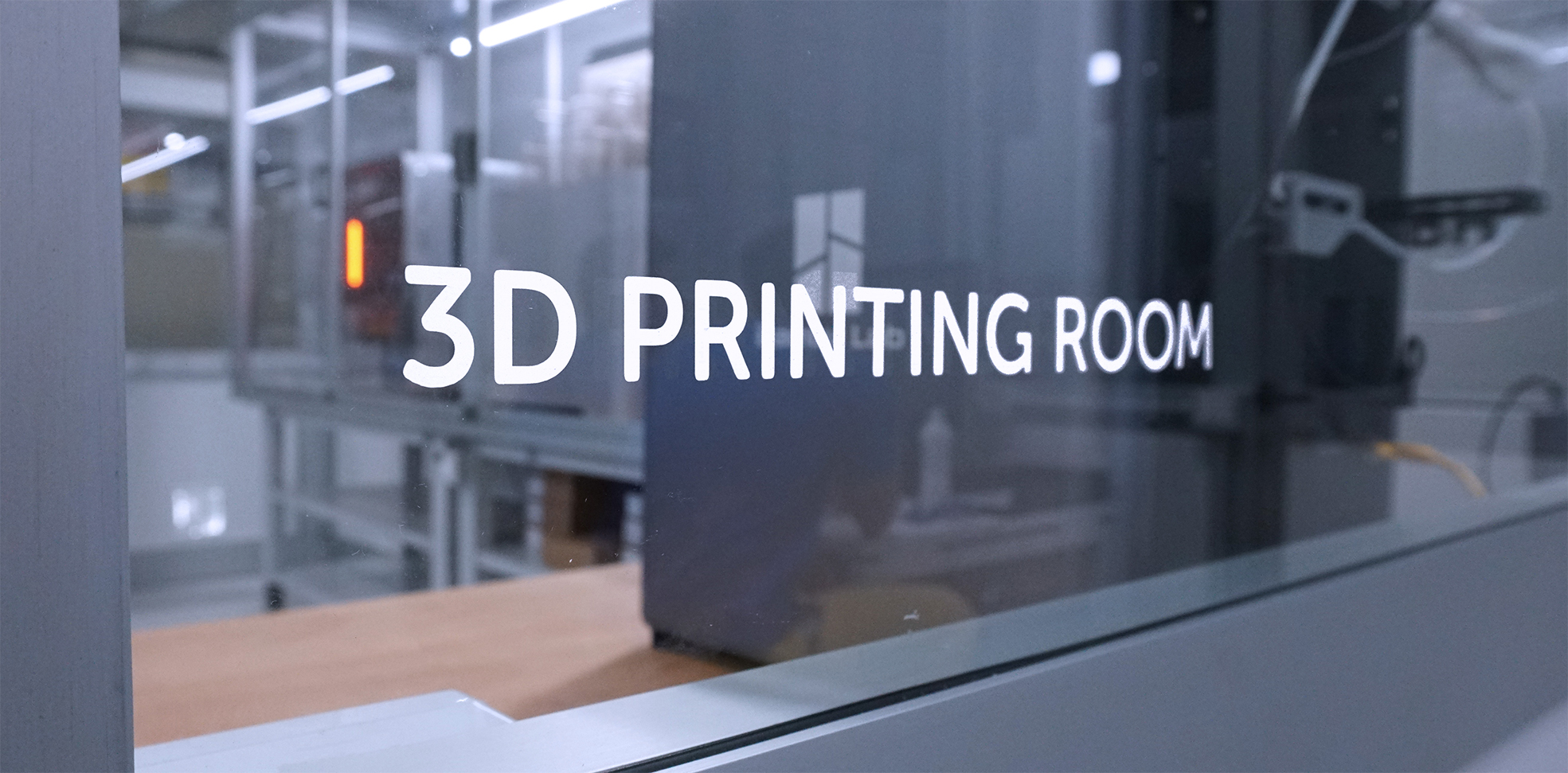

Prototipazione

SIPA offre una prototipazione efficiente di preforme e bottiglie, permettendoti di valutare rapidamente i tuoi concetti di imballaggio. Il nostro team di esperti, che lavora in una struttura di 10.000 metri quadrati con 12 macchine (tra cui sistemi a iniezione di preforme, monostadio e di soffiaggio), garantisce prototipi che rappresentano fedelmente il tuo prodotto finale.

Ingegnerizzazione del packaging

29

/

10

/

2025

Ingegnerizzazione del packaging

Noi di SIPA creiamo soluzioni di packaging che non solo catturano l'attenzione sullo scaffale, ma offrono anche grandi prestazioni. Il nostro team lavora a stretto contatto con voi per comprendere le vostre specifiche esigenze e obiettivi tecnici, e personalizza le soluzioni per ottimizzare le prestazioni, tenendo in considerazione fattori come la riduzione del peso, l'uso di materiali riciclati o materiali alternativi al PET.

Design

28

/

10

/

2025

Design

SIPA non si limita a progettare bottiglie; progettiamo interi ecosistemi di packaging che valorizzano il tuo marchio e lo fanno risaltare sullo scaffale. Con quarant'anni di esperienza nella produzione di macchinari per contenitori in PET, abbiamo una competenza ineguagliabile nel combinare il design del contenitore con le prestazioni.

News for this products

SIPA Additive: reimagined 3D printing fast prototyping

25

/

02

/

2026

SIPA Additive: reimagined 3D printing fast prototyping

SIPA has officially launched SIPA Additive, a new service designed to provide customers with a fast and cost-effective solution for packaging development. Located at the SIPA HQ Plant, the dedicated...

Intelligence in the mold: SIPA unveils XBRAIN for advanced digital management

While high-performance machinery is the backbone of PET production, the future of manufacturing lies in the data hidden within the mold. SIPA is proud to introduce XBrain, an advanced telemetric and...

Celebrating our sustainability achievements

13

/

01

/

2026

Celebrating our sustainability achievements

Celebrating our sustainability achievements: SIPA earns Gold Medal from Ecovadis With an overall score of 78/100 SIPA has been awarded a Gold medal from EcoVadis Sustainability Rating placing us...

XFORM Progress: From GEN 4 to PRO - setting new standards in high-cavitation PET preform production

12

/

12

/

2025

XFORM Progress: From GEN 4 to PRO - setting new standards in high-cavitation PET preform production

SIPA's XFORM RENEW wins Sustainability Awards 2025 for its efficient PET recycling tech, reducing CO₂ emissions and energy use while lowering costs.

SIPA's XFORM RENEW Wins Top Sustainability Award

13

/

11

/

2025

SIPA's XFORM RENEW Wins Top Sustainability Award

SIPA's XFORM RENEW wins Sustainability Awards 2025 for its efficient PET recycling tech, reducing CO₂ emissions and energy use while lowering costs.

25

/

02

/

2026

SIPA Additive: reimagined 3D printing fast prototyping

SIPA has officially launched SIPA Additive, a new service designed to provide customers with a fast and cost-effective solution for packaging development. Located at the SIPA HQ Plant, the dedicated...

27

/

01

/

2026

Intelligence in the mold: SIPA unveils XBRAIN for advanced digital management

While high-performance machinery is the backbone of PET production, the future of manufacturing lies in the data hidden within the mold. SIPA is proud to introduce XBrain, an advanced telemetric and...

13

/

01

/

2026

Celebrating our sustainability achievements

Celebrating our sustainability achievements: SIPA earns Gold Medal from Ecovadis With an overall score of 78/100 SIPA has been awarded a Gold medal from EcoVadis Sustainability Rating placing us...

12

/

12

/

2025

XFORM Progress: From GEN 4 to PRO - setting new standards in high-cavitation PET preform production

SIPA's XFORM RENEW wins Sustainability Awards 2025 for its efficient PET recycling tech, reducing CO₂ emissions and energy use while lowering costs.

13

/

11

/

2025

SIPA's XFORM RENEW Wins Top Sustainability Award

SIPA's XFORM RENEW wins Sustainability Awards 2025 for its efficient PET recycling tech, reducing CO₂ emissions and energy use while lowering costs.

Case Histories for this products

SIPA and Wahaha Group: a strong partnership for PET Preform Manufacturing in China

SIPA is proud to highlight its significant collaboration with Wahaha Group, a leading force in China's dynamic beverage industry. This strategic partnership underscores SIPA's commitment to...

SIPA and Arma Food: a collaborative approach to edible oil packaging in Egypt

The long-standing cooperation between SIPA and Arma Food is built on a shared commitment to quality and market-driven innovation.

Corporación AZENDE of Ecuador Boosts Production with SIPA Sincro Bloc Technology

Corporación AZENDE of Ecuador Boosts Production with SIPA Sincro Bloc Technology

Driving Innovation and Efficiency in PET Packaging

07

/

11

/

2025

Driving Innovation and Efficiency in PET Packaging

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

Driving Innovation and Efficiency in PET Packaging

07

/

11

/

2025

Driving Innovation and Efficiency in PET Packaging

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

SIPA and Sarl Noua: A Winning Partnership for the Algerian Beverage Market

Sarl Noua partners with SIPA to launch premium, sustainable mineral water, featuring innovative bottle design and high-speed production capabilities.

17

/

02

/

2026

SIPA and Wahaha Group: a strong partnership for PET Preform Manufacturing in China

SIPA is proud to highlight its significant collaboration with Wahaha Group, a leading force in China's dynamic beverage industry. This strategic partnership underscores SIPA's commitment to...

14

/

01

/

2026

SIPA and Arma Food: a collaborative approach to edible oil packaging in Egypt

The long-standing cooperation between SIPA and Arma Food is built on a shared commitment to quality and market-driven innovation.

10

/

12

/

2025

Corporación AZENDE of Ecuador Boosts Production with SIPA Sincro Bloc Technology

Corporación AZENDE of Ecuador Boosts Production with SIPA Sincro Bloc Technology

07

/

11

/

2025

Driving Innovation and Efficiency in PET Packaging

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

07

/

11

/

2025

Driving Innovation and Efficiency in PET Packaging

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

01

/

10

/

2025

SIPA and Sarl Noua: A Winning Partnership for the Algerian Beverage Market

Sarl Noua partners with SIPA to launch premium, sustainable mineral water, featuring innovative bottle design and high-speed production capabilities.