| MODELLO | CAPACITÀ |

| Xblend 12 | Fino a 12,000 l/h |

| Xblend 27 | Fino A 27,000 l/h |

| Xblend 34 | Fino a 34,000 l/h |

| Xblend 42 | Fino a 42,000 l/h |

| Xblend 54 | Fino a 54,000 l/h |

| Xblend 66 | Fino a 66,000 l/h |

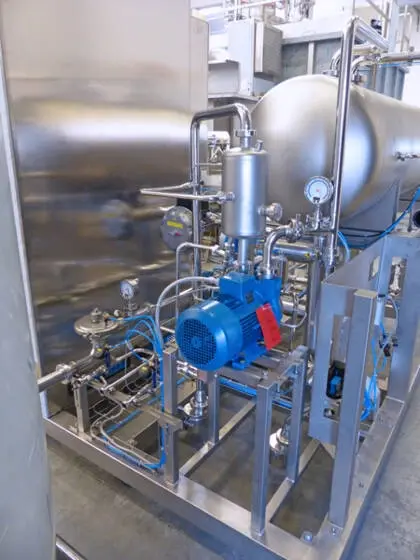

Deareazione

L'acqua in ingresso viene disaerata all'interno di un serbatoio tramite ugelli, in un'atmosfera ad alto vuoto (escludibile). Un misuratore di portata magnetico conta l'acqua che viene inviata al sistema di miscelazione utilizzando una pompa centrifuga.

Miscelazione

Lo sciroppo viene dosato con elevata precisione grazie al misuratore di portata massico. Un sistema in tempo reale controlla i dati caratteristici dello sciroppo per il mantenimento ottimale del rapporto di diluizione recuperando anche la fase di sciroppo pre-diluito.

Uno speciale diffusore è installato per ottenere un omogeneo discioglimento della quantità di sciroppo desiderata, inoltre la dispersione avviene grazie ad un successivo miscelatore statico che garantisce una fine miscelazione della bibita finita.

| MODELLO | CAPACITÀ |

| Xblend 12 | Fino a 12,000 l/h |

| Xblend 27 | Fino A 27,000 l/h |

| Xblend 34 | Fino a 34,000 l/h |

| Xblend 42 | Fino a 42,000 l/h |

| Xblend 54 | Fino a 54,000 l/h |

| Xblend 66 | Fino a 66,000 l/h |

Bevande non gassate.

While high-performance machinery is the backbone of PET production, the future of manufacturing lies in the data hidden within the mold. SIPA is proud to introduce XBrain, an advanced telemetric and...

Celebrating our sustainability achievements: SIPA earns Gold Medal from Ecovadis With an overall score of 78/100 SIPA has been awarded a Gold medal from EcoVadis Sustainability Rating placing us...

SIPA's XFORM RENEW wins Sustainability Awards 2025 for its efficient PET recycling tech, reducing CO₂ emissions and energy use while lowering costs.

SIPA's XFORM RENEW wins Sustainability Awards 2025 for its efficient PET recycling tech, reducing CO₂ emissions and energy use while lowering costs.

Discover SIPA's XLABL_RF, the cutting-edge roll-fed labelling machine that offers precision, flexibility, and efficiency for PET containers.

While high-performance machinery is the backbone of PET production, the future of manufacturing lies in the data hidden within the mold. SIPA is proud to introduce XBrain, an advanced telemetric and...

Celebrating our sustainability achievements: SIPA earns Gold Medal from Ecovadis With an overall score of 78/100 SIPA has been awarded a Gold medal from EcoVadis Sustainability Rating placing us...

SIPA's XFORM RENEW wins Sustainability Awards 2025 for its efficient PET recycling tech, reducing CO₂ emissions and energy use while lowering costs.

SIPA's XFORM RENEW wins Sustainability Awards 2025 for its efficient PET recycling tech, reducing CO₂ emissions and energy use while lowering costs.

Discover SIPA's XLABL_RF, the cutting-edge roll-fed labelling machine that offers precision, flexibility, and efficiency for PET containers.

The long-standing cooperation between SIPA and Arma Food is built on a shared commitment to quality and market-driven innovation.

Corporación AZENDE of Ecuador Boosts Production with SIPA Sincro Bloc Technology

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

Sarl Noua partners with SIPA to launch premium, sustainable mineral water, featuring innovative bottle design and high-speed production capabilities.

CGM bolsters its market leadership in the beverage industry by acquiring two more SIPA XFORM systems with 200-cavity molds.

The long-standing cooperation between SIPA and Arma Food is built on a shared commitment to quality and market-driven innovation.

Corporación AZENDE of Ecuador Boosts Production with SIPA Sincro Bloc Technology

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

Sarl Noua partners with SIPA to launch premium, sustainable mineral water, featuring innovative bottle design and high-speed production capabilities.

CGM bolsters its market leadership in the beverage industry by acquiring two more SIPA XFORM systems with 200-cavity molds.

Facci sapere come possiamo aiutarti. Abbiamo dei moduli di contatto dedicati a specifiche richieste, per assicurarci che la tua domanda raggiunga il reparto giusto e riceva una risposta rapida e precisa.

Drinktec | 2025